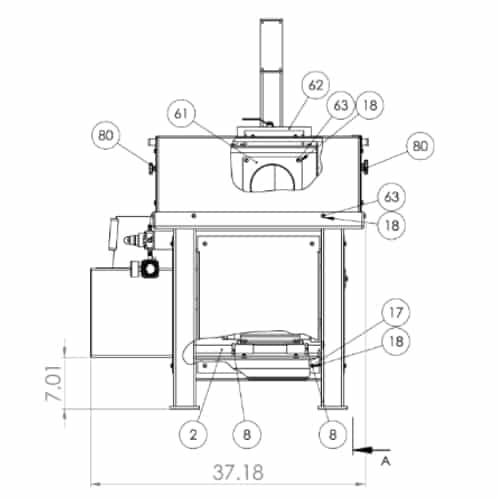

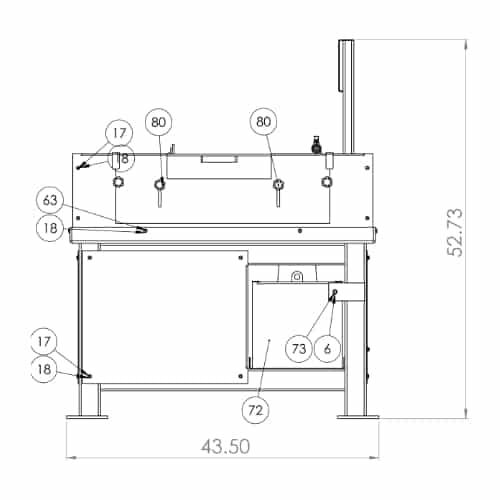

S8HW 8 X 60 INCH HORIZONTAL WET SANDER SPECIFICATIONS

- 7-1/2 HP 3 PH 220V and or 440V motor

- Belt size: 8″ x 60″

- Air belt tension (40-50 PSI required).

- Twin V-belt driven

- V-belt guard

- Magnetic controls

- 24V at on/off push buttons

- Sealed ball bearings in idler and drive pullies

- One knob belt tracking

- Heavy-duty steel stand

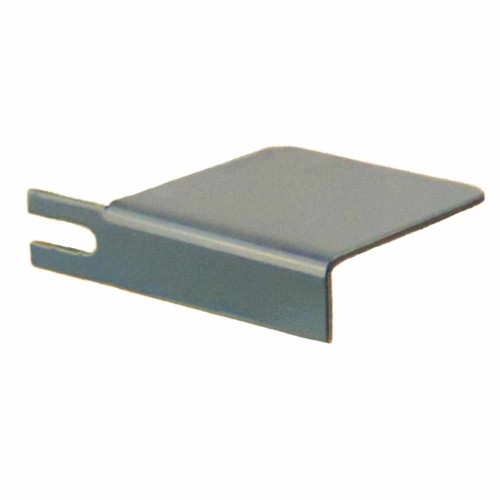

- Replaceable and reversible steel platen

- Platen working surface 8″ x 13″

- Flood coolant system: consists of a steel tank with a recirculating pump system and a coolant splash bar.

- Tank gallons: 16 gallons

- Machine position: horizontal

- Work stop/work rest

- Simple to replace parts

- Total shipping dimensions: L 64″ x W 40″ x H 63″

- Total shipping weight: 1000 lbs.

DESIGNED FOR THE FOLLOWING APPLICATIONS

- Beveling

- Deburring

- Square-up ends

- Round flat corners

- Flattening

- Polishing metal for analysis/inspection

- Flatwork

- Surface preparation

- Surface Conditioning

- Removal of oxidation and dross

- Surface conditioning

WET SANDER REPLACEMENT PARTS TO KEEP ON THE SHELF

S8HW 8 X 60 INCH HORIZONTAL WET SANDER REPLACEMENT PARTS

Replacement parts for the S8H 8 x 60 large wet belt sander are available to buy and ship within a few business days. If you want to purchase your belt sander repair parts, click here.