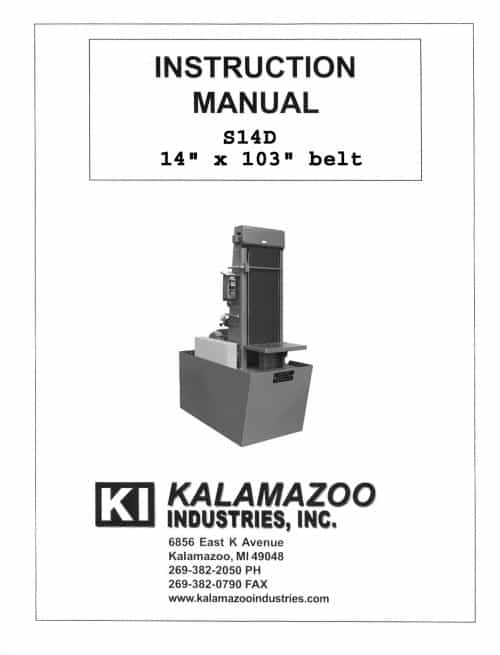

Kalamazoo S10W 10 x 90 Inch Wet Production Sander

The Kalamazoo S10W 10 x 90 inch wet production sander is designed to streamline your metalworking operations. Its generous work surface accommodates larger pieces, boosting output and reducing handling time. Wet sanding capabilities minimize dust for worker safety and enhance surface finishes. Built for demanding environments, this robust sander delivers the reliable performance you need to maximize production while achieving superior results.

Wet Sander Specifications

Motor Specifications

- Powerful and Versatile: 10 HP 3PH motor, available in 230V (24 amps) or 460V (12 amps) configurations.

- Efficient Pump Operation: Coolant pump draws 0.9 amps (230V) or 0.52 amps (460V).

Controls and Safety

- Reliable Operation: Magnetic controls for safe and dependable performance.

- Convenient Control: 24V on/off switch and sanding belt jog selector for precise adjustments.

Key Components

- Coolant System: 10-gallon steel tank with pump and splash bar for effective wet sanding.

- Workpiece Capacity: Accommodates sanding belts up to 10″ x 90″.

- Optimal Speed: Belt speed of 3500 SFPM for efficient material removal and finishing.

Work Area

- Durable Platen: Large 10″ x 29″ reversible and replaceable steel platen for extended use.

- Versatile Work Surface: 10″ x 28″ cast iron work table with fixture slot and tilting capability (45° down, 15° up).

Additional Details

- Easy Belt Changes: Air tension system (40-50 PSI required).

- Drive System: Reliable V-belt driven design.

- Shipping: Dimensions: L 48″ x W 53″ x H 80″. Weight: 1600 lbs.

This Versatile Wet Sander Tackles a Wide Range of Tasks

- Beveling

- Deburring

- Squaring up ends

- Rounding corners

- Flattening

- Polishing

- Material sampling prep

- Production sanding

- Smoothing”

S10W 10 x 90 Inch Wet Production Sander Options

- KWB109050 10″ x 90″ 50 grit aluminum oxide sanding belt

- KWB109080 10″ x 90″ 80 grit aluminum oxide sanding belt

- KWB1090100 10″ x 90″ 100 grit aluminum oxide sanding belt

- Variable frequency drive

Essential S10W Production Sander Replacement Parts for Your Kalamazoo Sander

Parts are in stock in Kalamazoo and ship out in few days once the order has been placed. Click here to buy your S10 10 x 90 inch wet metalworking sander replacement parts today!