Ebook: Cutoff Saw Creates Blanks from Superalloy's in Seconds

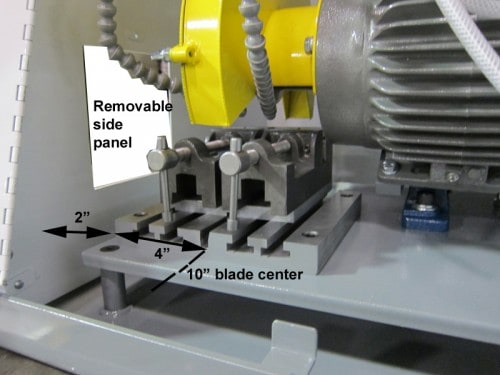

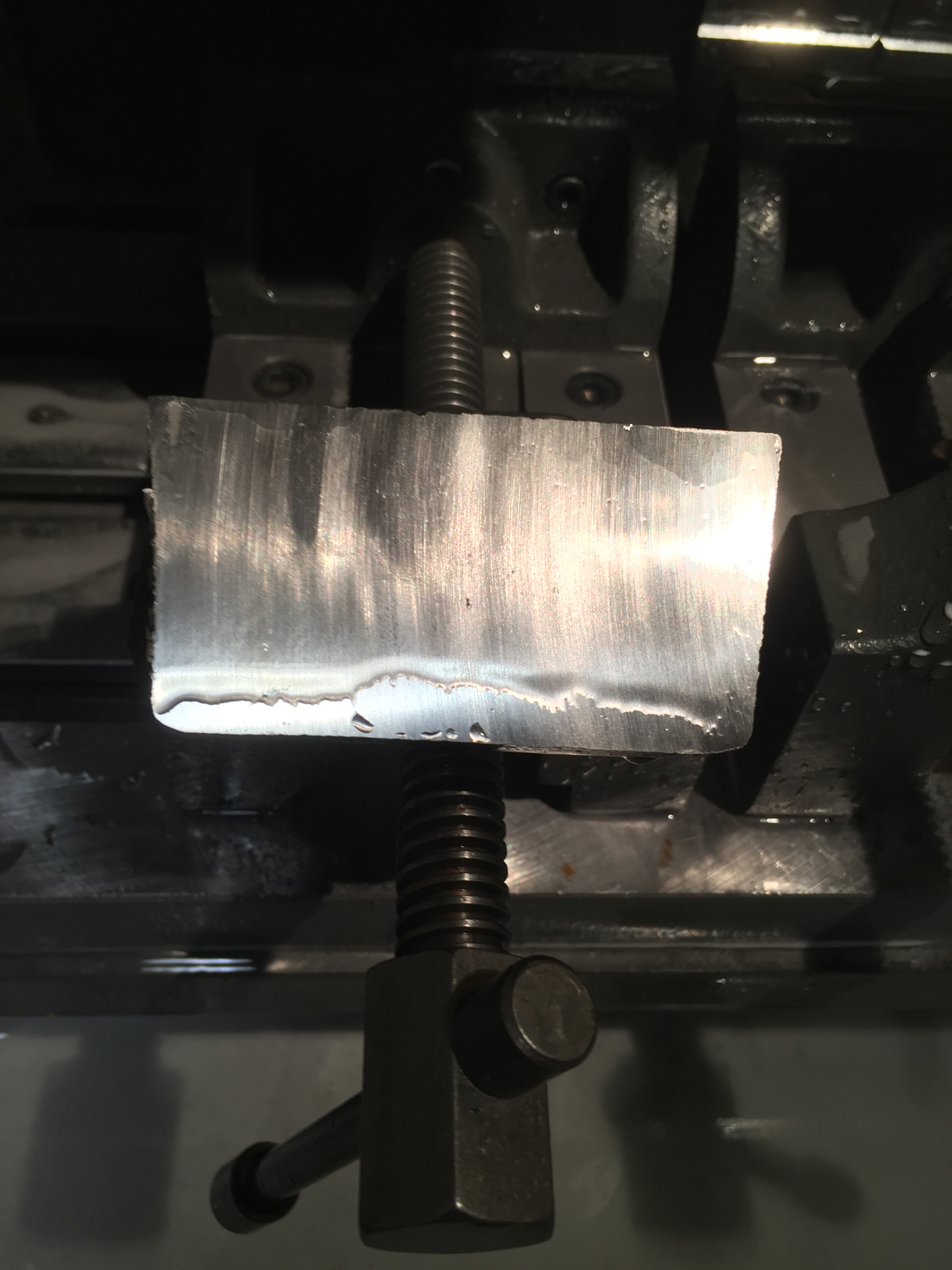

The superalloy inconel is valued for its strength and heat resistance, but these properties also make it difficult to machine. Northern A-1 Services, a recycling company with facilities throughout Northern and Western Michigan and in Pennsylvania, needed to saw inconel bar stock without using coolant to create casting charges on a just-in-time (JIT) delivery schedule for an aerospace customer. Given the time constraints—and sawing operation in general—the company realized it would need a better cutoff saw than what it had. As a result, the company turned to Kalamazoo Industries of Kalamazoo, Michigan, to develop a cutoff saw capable of dry-cutting inconel bar stock in a matter of seconds rather than minutes. As it turns out, the 12-feet-tall cutoff saw Kalamazoo Industries delivered with a 75-hp motor and 36-inch-diameter abrasive wheel turned a challenging operation into a repeating source of job-shop-type revenue for the recycling company. Down load for free to read the whole article.