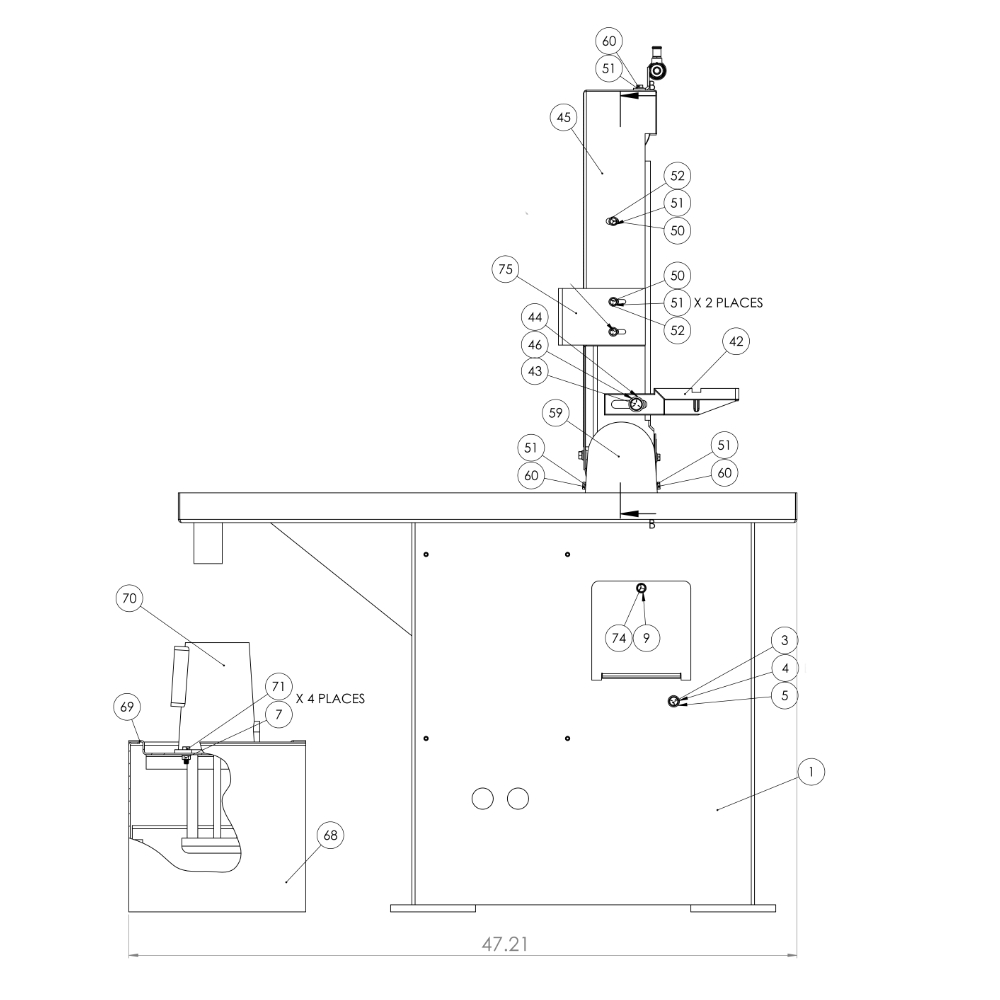

Kalamazoo S660MW 6 x 60 Inch Industrial Wet Sander

The Kalamazoo Industries S660MW 6 x 60 inch wet belt sander offers powerful sanding, polishing, and deburring with a flood coolant system. Its adjustable design makes it versatile for various applications.