A fabricator that can find the right abrasive wheel for the job, can figure out the right cutting speed and downfeed rate, and can find the right saw with enough power likely doesn’t have to worry about poor quality cuts while abrasive cutting.

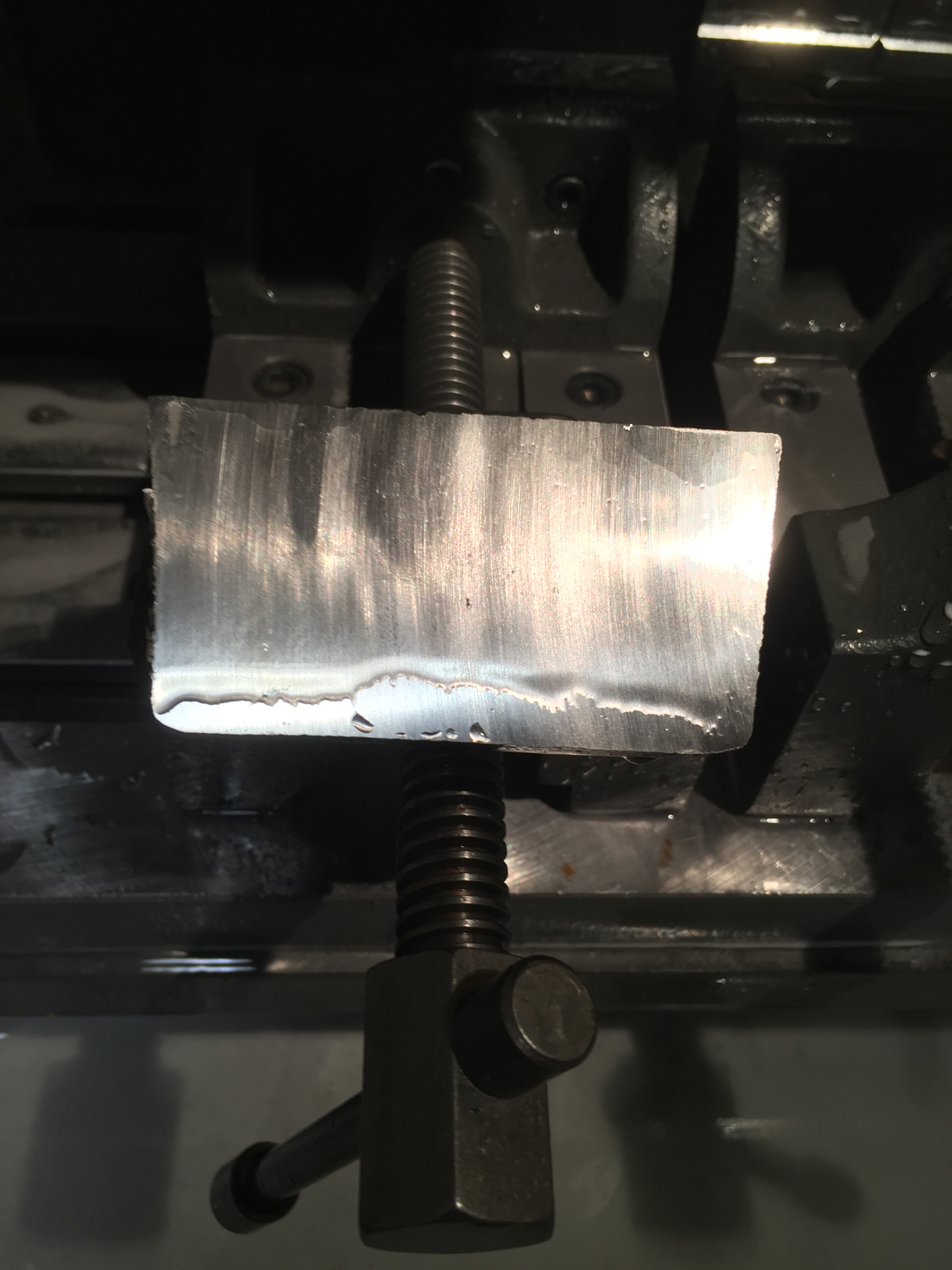

Change in cut quality is a common problem, even when the abrasive saw has been optimized for the type of cut desired. Changes might not appear when you are cutting small diameter stock, but put in a larger piece of the same material and soon you will see scorch marks and a ragged edge…

Read the entire article for free by adding to cart –