Description

Making the abrasive cutoff saw work for you

How to optimize your abrasive saw to achieve ideal cuts

THE FABRICATOR® MAY 2011

MAY 6, 2011

BY: SCOTT ALLEN

Providing exact advice on how to get optimal performance from an abrasive cutoff saw is very difficult because each application is unique. Rough guidelines, however, can help a metal fabricator understand the cutting process, troubleshoot problem areas, and determine the right equipment for the cutting job.

For many companies an abrasive saw is simply a functional way to cut something. However, those same companies may use the saw in very different ways to achieve certain outcomes:

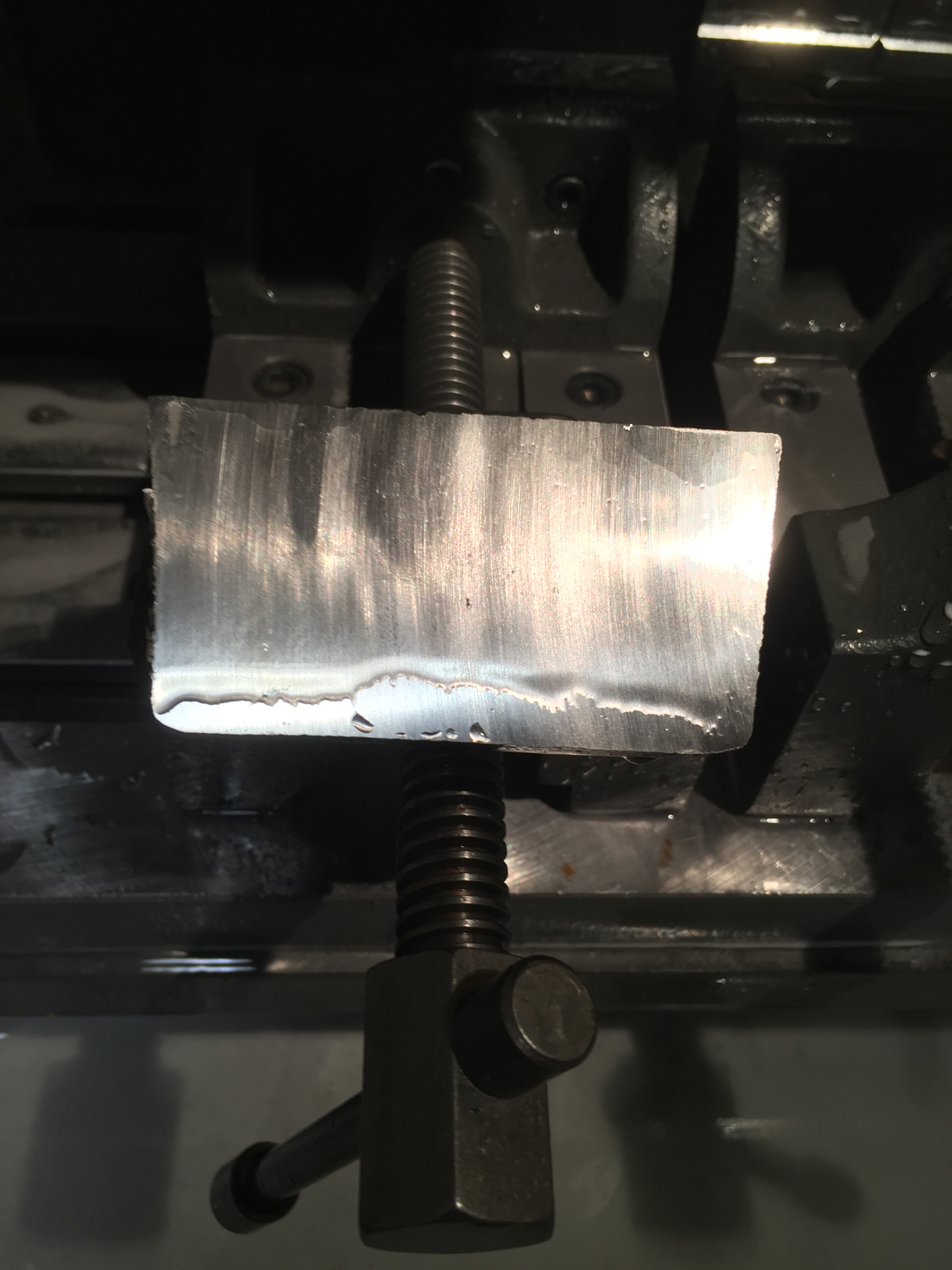

- If you are sawing rebar to length, what the end of the stock looks like is unimportant, or if your workpiece is destined for additional machining, a functional cut may be completely acceptable (see Figure 1).

- If you are cutting stock that will be welded or you want an end that doesn’t need machining, you want an ideal cut—smooth ends without any scorching and clean edges (see Figure 2). No secondary finishing such as grinding or polishing is required.

- If you are using an abrasive saw for destructive testing as part of your quality control program, the surface must be more than just smooth; it must be an ideal metallurgical cut, polished to a mirror finish to facilitate inspection (see Figure 3).

Sometimes achieving an acceptable cut can be a frustrating situation. You can go for weeks making ideal cuts and then, seemingly without reason, the quality drops. Or you have successfully cut 0.5-inch stock, but cutting the same material that’s 2 in. thick does not produce the results you want. This can seem to be a mystery, but if you understand how to optimize your abrasive saw for each specific cutting application, you will be able to achieve that ideal cut.

Visit the fabricator website to read more: http://www.thefabricator.com/article/sawing/making-the-abrasive-cutoff-saw-work-for-you