A fabricator that can find the right abrasive belt for the next job. Their many different belts available and each job and each style will give you a different finish. Their are :

- Open Coat Belt- this form of sanding belt has gaps and spaces so the material won’t clog the belt. This abrasive belt is used mostly with woodworking.

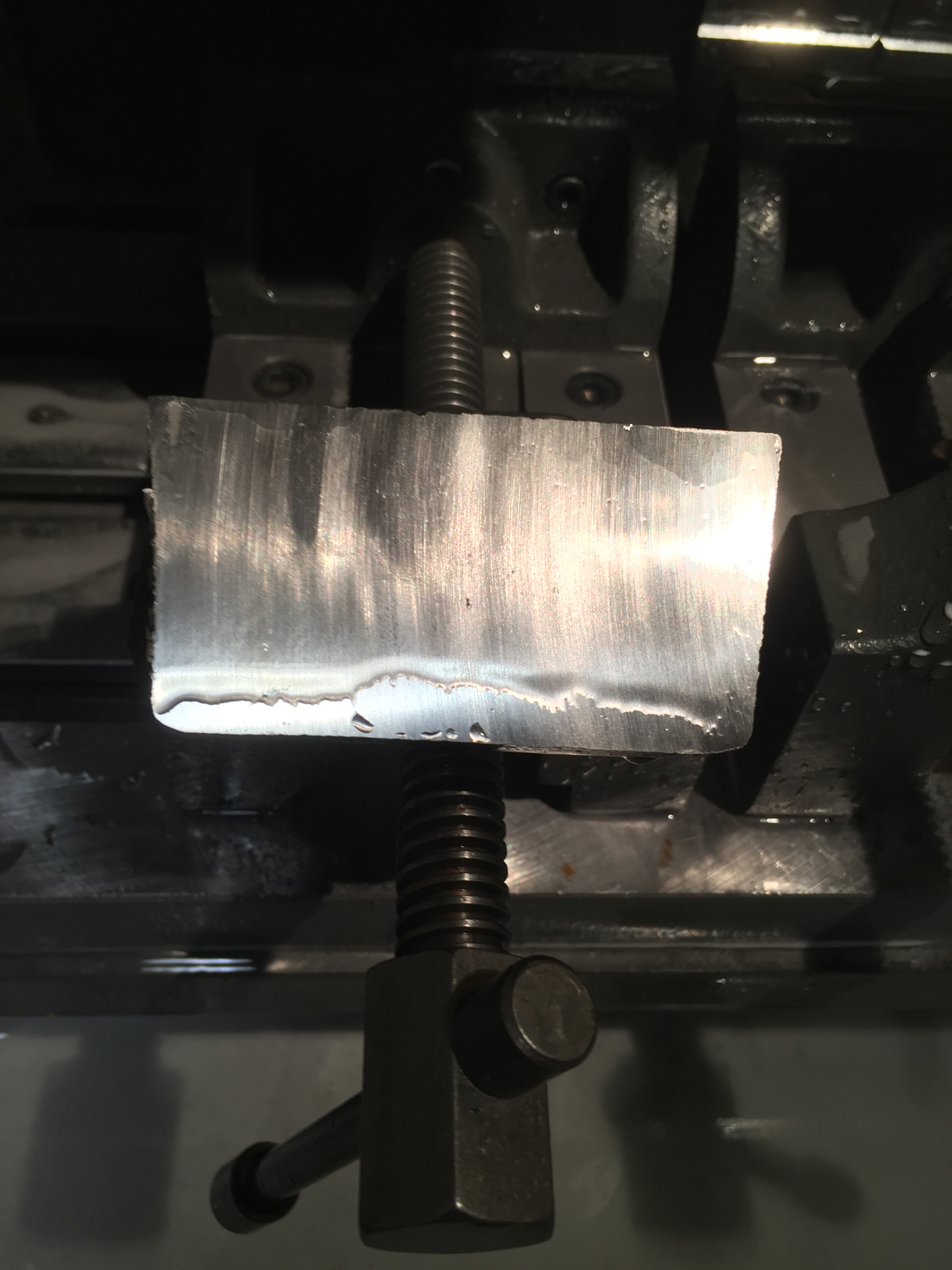

- Closed Coat Belt– this form of sanding belt doesn’t have gaps or spaces which make this sanding belt is designed and manufactured for sanding or grinding metals.

Quality will vary with each belt read the entire article for free by adding to cart.