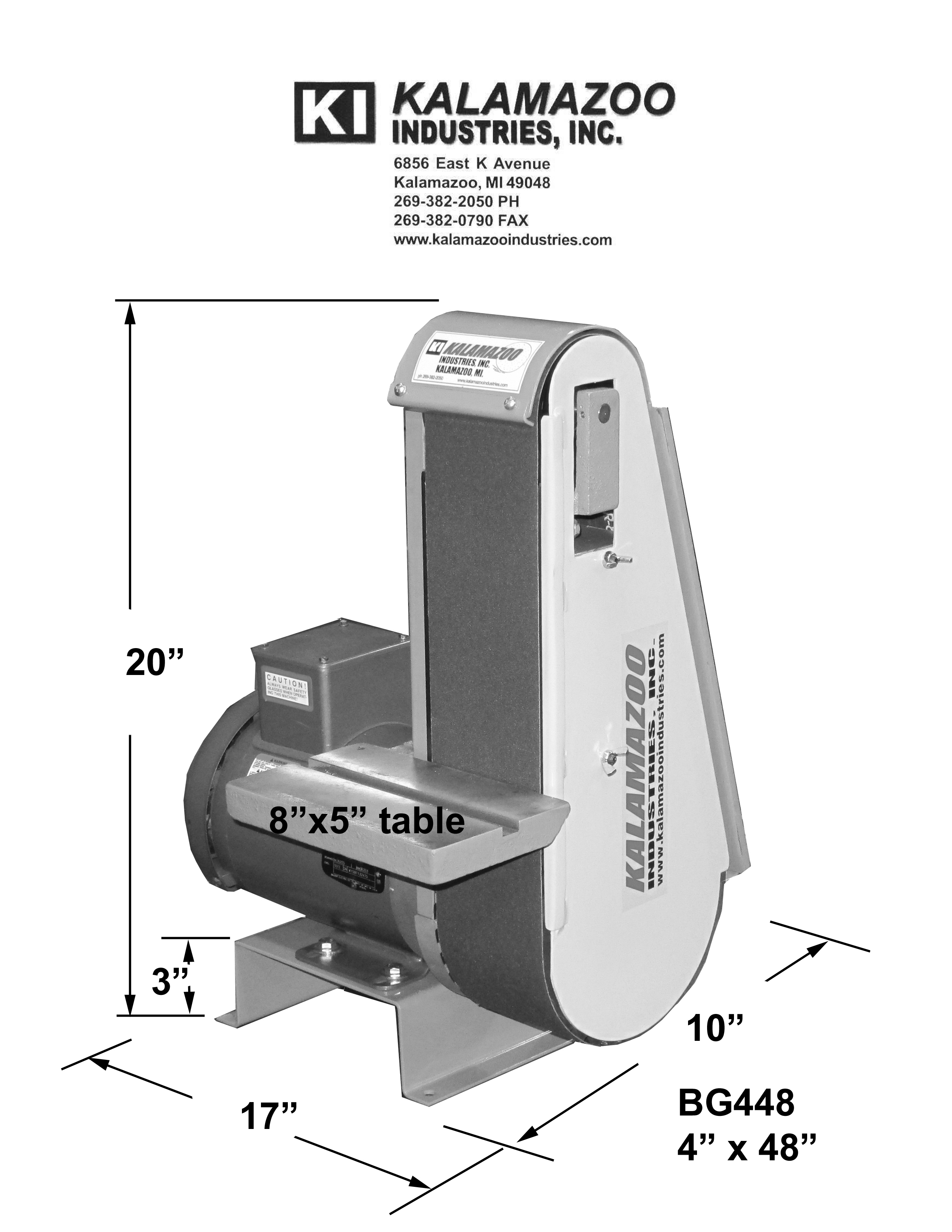

BG448 4 X 48 INCH HEAVY DUTY BELT GRINDER

The BG448 4 x 48 industrial abrasive belt grinder is a multi-position grinding machine with multiple sanding locations and a belt speed of 7200 that keeps your metal cool while grinding.

Other BG448 features a powerful 3HP 1PH 3PH so the operator can remove a large amount of material and not burn the motor up, removable platen, adjustable cast iron work table, and 8″ x 4″ serrated 70 duro contact wheel.

BELT GRINDER SPECIFICATIONS

- 3HP 1PH TEFC motor, 110 or 220V (specify at time of order) and or 3PH 220v or 440V (specify voltage at the time of order).

- 1 phase amp draws: 115V FLA is 24 amps, and 230V FLA is 12 amps

- 3 phase amp draws: 230V FLA is 8.4 amps, and 480V FLA is 4.2 amps

- Rotary on/off switch.

- Belt speed: 7200 SFPM

- Adjustable 8″ x 8″ cast iron work table with a 5/8th slot.

- Multi-position belt grinding head from (From vertical to horizontal and any position in between).

- 4″ x 48″ abrasive belt. It can accommodate various belt types so you can achieve your desired finish.

- Steel construction

- Quick belt change mechanism.

- Adjustable 8″ x 8″ cast iron work table with a 5/8th slot. The worktable can be adjusted from 0° to 45° down.

- Removable and replaceable steel platen. Platen work surface: W 4″ x H 10″.

- 8″ x 4″ 70 duro serrated contact wheel.

- Full work movement from left to right.

- BG448 shipping weight: 140 LBS.

- BG448 shipping dimensions: L 27″ X W 27″ X H 33″.

- BG448S (with stand) shipping weight: 300 LBS.

- BG448S (with stand) shipping dimensions: L 43″ X W 40″ X H 62″.

OTHER MODELS

- BG448S 4 x 48 belt grinder with steel stand

DESIGNED TO DO THE FOLLOWING

- Bevel

- Deburr

- Squaring up ends

- Rounding corners

- Flatwork

- Contouring

- Heavy metal removal

- Rust removal

- Flattening round corners

- Metal grinding

BG448 4 X 48 INCH HEAVY DUTY BELT GRINDER REPLACEMENT PARTS

Replacement parts for the BG448 x 48 inch heavy-duty belt grinder are in stock and shipped out within a few business days of ordering those parts. Click here to buy your repair parts.