Engineered for heavy-duty performance, the KM14 14″ abrasive metal cutting saw is your go-to solution for fast, accurate, and reliable metal cutting. Built with a rugged steel base and powered by a robust 5HP motor, this saw for steel cutting delivers high-speed performance at 4400 RPM—perfect for demanding fabrication environments. It’s a top contender for anyone searching for the best mitre saw for industrial metal applications.

Whether you’re cutting mild steel, structural tubing, or angle iron, the KM14 steel cut off saw offers unmatched versatility with its 45° mitre capability and dual cam lock vises that secure your material for clean, consistent cuts every time.

.

The equipment operator can efficiently cut mild steel with the right cutoff wheel and will cut mild steel fast with the KM14 14 inch industrial mitre chop saw. The KM14 mitre saw features a powerful 5HP 1PH or 3PH motor, dual cam lock vises, 4400 RPM at the spindle, a 1″ spindle arbor, and a steel stand.

Cutting Capabilities

- Supports 12″ to 14″ reinforced abrasive cutoff wheels

- Approximate Cutting Capacities – 14″ Saw (Mild Steel)

- 2.50″ Solid Stock

- 3.00″ Pipe

- 2.30″ at 45°

- Mitres left or right up to 45° with positive index holes

Motor & Electrical

- 5 HP motor

- Voltage options:

- Single Phase: 220V

- Three Phase: 220V or 440V (specify at time of order)

- Amp draw:

- 3 PH: 230V – 11.8 amps | 460V – 5.9 amps

- 1 PH: 230V – 19.5 amps

- Spindle speed: 4400 RPM

- Magnetic ON/OFF switch

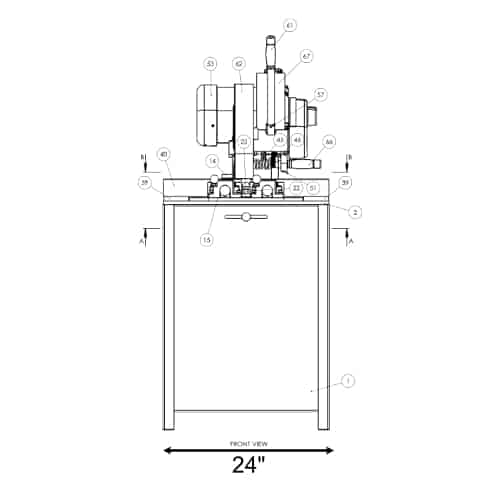

Construction & Components

- Cast iron saw arm

- Cast iron trunnion

- Heavy-duty steel base

- Industrial sealed ball bearings

- Standard dual cam lock vises

- Adjustable up/down stops

Shipping Information

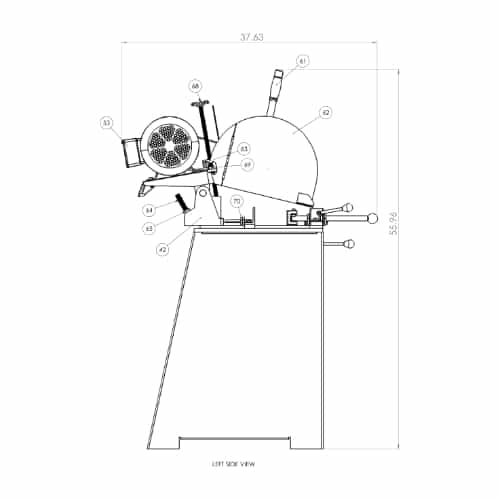

- Dimensions: 43″ (L) x 45″ (W) x 63″ (H)

- Weight: 400 lbs.

- Shipping weight and dimensions are subject to change

Country of Origin

- Made in USA

The Kalamazoo Industries KM14 14″ abrasive mitre saw is your go-to solution for tough industrial cutting jobs. Powered by a robust 5 HP motor and built with a rugged frame, this metal cutting saw delivers fast, clean, and accurate cuts across a wide range of materials. Whether you’re in metal fabrication, automotive, or the energy sector, the KM14 steel cut off saw is engineered to handle demanding tasks with the reliability and precision professionals count on. As a trusted saw for steel cutting, it’s a top choice for those seeking the best mitre saw for industrial applications.

Key Task

- Straight Cuts on Solid Bar Stock

- Cut mild steel round, square, or flat bar up to 2.5″ thick

- Ideal for prepping material for welding, machining, or assembly

- Pipe and Tube Cutting

- Clean cuts on mild steel pipe up to 3″ in diameter

- Suitable for structural tubing, conduit, and mechanical piping

- 45° Mitre Cuts

- Precision angled cuts on angle iron, flat bar, or tubing

- Useful for frame fabrication, brackets, and angled joints

- Bundle Cutting

- Cut multiple rods or tubes at once using secure clamping

- Increases productivity in repetitive cutting operations

- Cutting Structural Shapes

- Efficiently cuts angle iron, channel, and small I-beams

- Perfect for light structural fabrication and modification

- Notching and Fit-Up Prep

- Prepares ends of material for welding or assembly

- Ensures tight, clean joints for fabrication

- On-Demand Shop Fabrication

- Quick, accurate cuts for custom brackets, supports, and fixtures

- Ideal for maintenance and repair operations (MRO)

The Kalamazoo KM14 14″ abrasive mitre saw is engineered to tackle the toughest industrial cutting jobs with precision and power. Designed specifically for cutting mild steel quickly and accurately, it features a robust 5 HP motor, precision mitre adjustments, and a heavy-duty steel base built to withstand demanding use. Whether you’re cutting solid stock, pipe, or angled materials, the KM14 delivers clean, consistent results—on the shop floor or in the field. Trusted by fabrication professionals, it’s a reliable metal cutting saw and a proven saw for steel cutting that earns its place among the best mitre saw options for performance, durability, and productivity.

Key Benefits

- Powerful 5 HP Motor

Cuts through mild steel quickly and efficiently with single- or three-phase options. - Versatile Cutting Capacity

Handles up to 2.5″ solid stock, 3″ pipe, and 2.30″ at 45° mitre angles. - Precision Mitre Cuts

Mitres left or right up to 45° with positive index stops for repeatable accuracy. - Durable Construction

Cast iron saw arm and trunnion, industrial sealed bearings, and a steel base ensure long-term reliability. - Fast Blade Speed

4,400 RPM spindle speed for clean, efficient abrasive cutting. - Secure Workholding

Dual cam-lock vises keep material firmly in place during cuts. - User-Friendly Operation

Magnetic ON/OFF switch and adjustable up/down stops for safety and convenience.

This maintenance checklist is designed to ensure the optimal performance and longevity of the KM14 14-Inch Industrial Abrasive Mitre Chop Saw from Kalamazoo Industries. Regular maintenance helps prevent breakdowns, ensures operator safety, and maintains cutting accuracy.

Daily Maintenance

- Inspect the abrasive wheel for cracks or wear before use.

- Check for loose or damaged V-belts. Tighten or replace both as needed.

- Clean the machine surface and work area of dust and debris.

- Ensure the safety guard is securely in place and functioning.

- Verify that the vise clamps are operating smoothly.

- Check for unusual noises or vibrations during operation.

Weekly Maintenance

- Inspect the spindle and arbor for wear or damage.

- Inspect the magnetic on/off switch for proper operation.

- Tighten any loose bolts or fasteners.

Monthly Maintenance

- Check the integrity of the cast iron saw arm and trunnion.

- Test the machine’s electrical components for proper function.

- Inspect the bearings for signs of wear or noise.

- Perform a comprehensive inspection of all mechanical and electrical components.

- Replace worn or damaged parts such as v-belts, bearings, and switches.