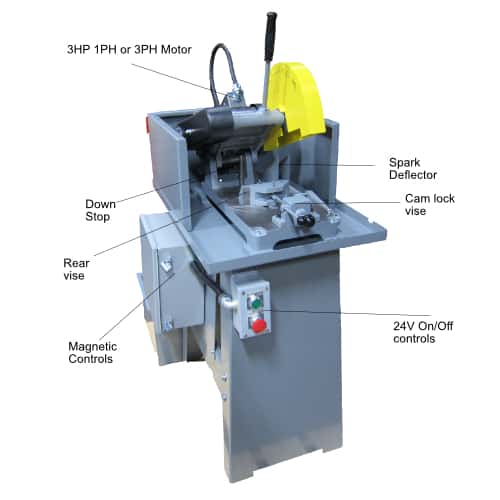

The K10SW 10″ Wet Abrasive Chop Saw

The Kalamazoo K10SW delivers cool, clean, weld-ready cuts every time. Its built-in flood coolant system eliminates heat and produces smooth, burn-free edges on mild steel, stainless, and structural metal — no extra grinding needed. The powerful 3HP motor handles solids up to 1.5″ and pipe up to 2.5″, moving your shop through sample preparation and prototype machining jobs faster.

A single cam lock vise and adjustable depth stops ensure square, repeatable cuts for strict quality control standards. Whether you’re building precision metal products or running production all day, this American-made saw delivers. Built on a cast iron base with a heavy-duty steel stand, it’s designed to take the punishment day after day.

Put the K10SW to Work in Your Shop

Ready to cut cooler, cleaner, and faster? Call Kalamazoo Industries at (800) 592-2050 or request a quote today.

K10SW Resources

Presentation Downloadable

Product Info Maintenance KI YouTube

Channel Newsletter Request

a Quote Parts Store

Made in

Made inthe USA

Why Shop Owners Choose the K10SW

The Kalamazoo K10SW 10-inch wet abrasive chop saw gives your shop the power to cut metal cooler, cleaner, and faster. Its 3HP motor drives through mild steel, stainless steel, and cast iron with ease, while the built-in flood coolant system prevents heat buildup and burn marks. Your parts come out smooth and ready for the next step.

Built for Sample Preparation, Quality Control, and Production

Save time on grinding and rework while keeping your production line moving. Whether you need accurate cuts for sample preparation, tight-tolerance work for quality control, or quick turnarounds for prototype machining, the K10SW delivers consistent results shift after shift. This American-made saw handles precision metal products and structural metal with the dependability shop owners count on every day.

K10SW Performance and Cutting Power

- Clean, Burn-Free Cuts Every Time – The 10-gallon flood coolant system keeps your material cool during cutting. Smooth edges move straight to welding or assembly without extra finishing.

- Powerful 3HP Motor That Won’t Quit – Cuts through 1.5-inch solids and 2.5-inch pipe without slowing down. More time cutting, less time waiting — even on harder alloys.

- Rock-Solid Workholding for Repeatable Accuracy – The single cam lock vise grips your workpiece tight so it won’t shift mid-cut. The adjustable down stop dials in cut depth for repeatable quality control on every piece.

Durability, Versatility, and American Quality

- Built Tough for Daily Shop Use – A cast iron base, cast aluminum saw arm, and heavy-duty steel stand support years of hard work. This saw stands up to the daily grind your shop demands.

- Supports Multiple Applications Across Your Shop – From sample preparation and prototype machining to production runs of structural metal and precision metal products, the K10SW handles it all.

- Made in the USA – Kalamazoo Industries builds every K10SW with American craftsmanship and quality materials. A saw backed by a company that stands behind its products.

Motor

- Powerful 3HP 1PH or 3PH 3450 RPM motor

- 1PH Amp Draw: 230V 12 amps

- 1PH Pump Amp Draw: 230V 3 amps

- 3PH Amp Draw: 230V 8.4 amps / 460V 4.2 amps

- 3PH Pump Amp Draw: 230V 0.9 amps / 460V 5.2 amps

Cutting Capacity

- Materials: 1.5″ solids, 2.5″ pipe

- Cutoff Wheel: Up to 10″ abrasive wheel

- Note: Abrasive wheel not included

Features

- Magnetic controls with 24V on/off switch

- Spindle arbor: 5/8″

- Spindle speed: 2300 RPM

- Integrated flood coolant system with flexible nozzle

- Replaceable cam lock vise

- Adjustable up and down stops

- Adjustable work length stop

Construction

- Cast iron saw base and trunnion

- Cast aluminum saw arm

- Heavy steel stand

- Steel slash guard

- 10-gallon steel coolant tank

Dimensions & Weight

- Shipping dimensions: 51″ L x 37″ W x 63″ H

- Shipping weight: 400 lbs crated

- Shipping weight and dimensions are subject to change

Country of Origin

- Made In USA

Wet Abrasive Cutting for Demanding Shop Applications

The Kalamazoo K10SW 10-inch wet abrasive chop saw cuts metal wet — cleanly, accurately, and without the heat damage that slows production. Its 3HP motor and built-in flood coolant system deliver burn-free cuts on mild steel, stainless steel, cast iron, and alloy steels. Your materials stay cool and true from the first cut to the last. Whether you need to prepare stock for welding, size blanks for machining, or keep up with high-volume orders, this American-made saw handles it all.

Lab and Quality Applications

- Sample Preparation — Labs and testing facilities use the K10SW to cut precise test coupons and material samples. The coolant system prevents heat distortion, so your samples stay accurate and ready for analysis right off the saw.

- Quality Control — Consistent, repeatable cuts support your quality control process from start to finish. The adjustable down stop and cam lock vise hold tight tolerances, so every piece meets spec without rework.

Production and Fabrication Applications

- Prototype Machining — When your shop takes on prototype machining projects, speed and accuracy matter most. The K10SW lets you rough-cut bar stock and plate quickly, so your CNC machines spend less time removing excess material.

- Precision Metal Product Fabrication — Shops that build any precision metal product count on clean edges and square cuts. The flood coolant eliminates burrs and burn marks, so your parts are ready for the next step immediately.

- Structural Metal Cutting — For shops that work with structural metal like angle iron, channel, and tubing, the K10SW handles solids up to 1.5 inches and pipes up to 2.5 inches. The heavy-duty cast iron base and steel stand hold steady through every cut, even during long production runs.

Additional Equipment Images and Videos

K10SW Frequently Asked Questions

The K10SW is a 10-inch industrial wet abrasive chop saw made in the USA. Its flood coolant system delivers clean cuts on steel, stainless, and cast iron. Built for welding shops, fabrication shops, machine shops, and CNC machining companies.

Mild steel, stainless steel, cast iron, and alloy steels. The coolant keeps temperatures low so you can cut harder metals without heat damage.

Solid round stock up to 1.5" and pipes up to 2.5" in diameter. These ratings are based on mild steel. The saw uses a 10-inch abrasive cutoff wheel, sold separately.

A built-in pump circulates coolant from a 10-gallon steel tank through a flexible nozzle directed at the cut zone. This keeps the blade and material cool, prevents burn marks, and extends the life of your abrasive wheels.

Ships at 51" L x 37" W x 63" H and weighs about 400 lbs crated. Once set up, it has a compact footprint that fits well in most shops.

The coolant system prevents heat-affected zones so your material properties stay intact. That means fewer rejects, less rework, and a better finished product.

Cast iron base, cast aluminum saw arm, and heavy-duty steel stand. This construction absorbs vibration and holds up to daily industrial use year after year.

Proudly made in the USA by Kalamazoo Industries with quality materials and American craftsmanship.

Cut Cooler. Cut Cleaner. Cut with the K10SW.

Cooler cuts through steel, stainless, and hard alloys — the 10" wet saw built for shops that never stop.

Call (269) 382-2050 or Request a Quote today.

Made in USA | Compact Footprint | Trusted in Machine & Fab Shops