Useful Tips and Tricks For Your Kalamazoo Industries Industrial Equipment

We want to help you when and however we can with our equipment. We want to make sure that you are successful and can get the most out of the Kalamazoo equipment. Below we’re putting together “Useful Tips and Tricks For Your Kalamazoo Industries Industrial Equipment” that we’ve developed or discovered over the years.

We will be covering a variety tips and tricks topics that will assist you in maintaining your Kalamazoo Industries equipment. Those topics include but not limited to the following:

- How to measure your sanding belt

-

Changing v-belts

- Weekly cleaning

- How to check for crown on your pulley

- Part placement in cutoff saw

How to measure your sanding belt:

Do you have a belt sander from Kalamazoo Industries and your sanding belt is worn out and you need to replace it, but the problem is your not sure what the belt length is below are a couple of examples of how to figure out what.

Example One: take the used sanding belt off the belt sander cut the belt from end to end that will give you the length. You will also want to measure the width of the belt. (Example A)

Example Two: On a new belt you will want to flatten the belt measure from end to end then times it by two. For example for a 1 x 42 inch belt (21 x 2 = 42) then measure the width is 1″ that will give you a the overall belt measurement of 1″ x 42″. (Example B)

Changing V-Belt On The 14″ Cutoff Saw

Changing the v-belt on your 14″ cutoff saw has to be done from time to time (depending on how much usage the saw gets). It’s a straight forward project and can be complete and you can be back to work in about 20 minutes if done correctly.

With that in mind you will need to keep the v-belt pulleys parallel to each other. This help maintain the belt life and runs properly on the v-belt pulley’s.

Placing the part correctly in the cutoff saw

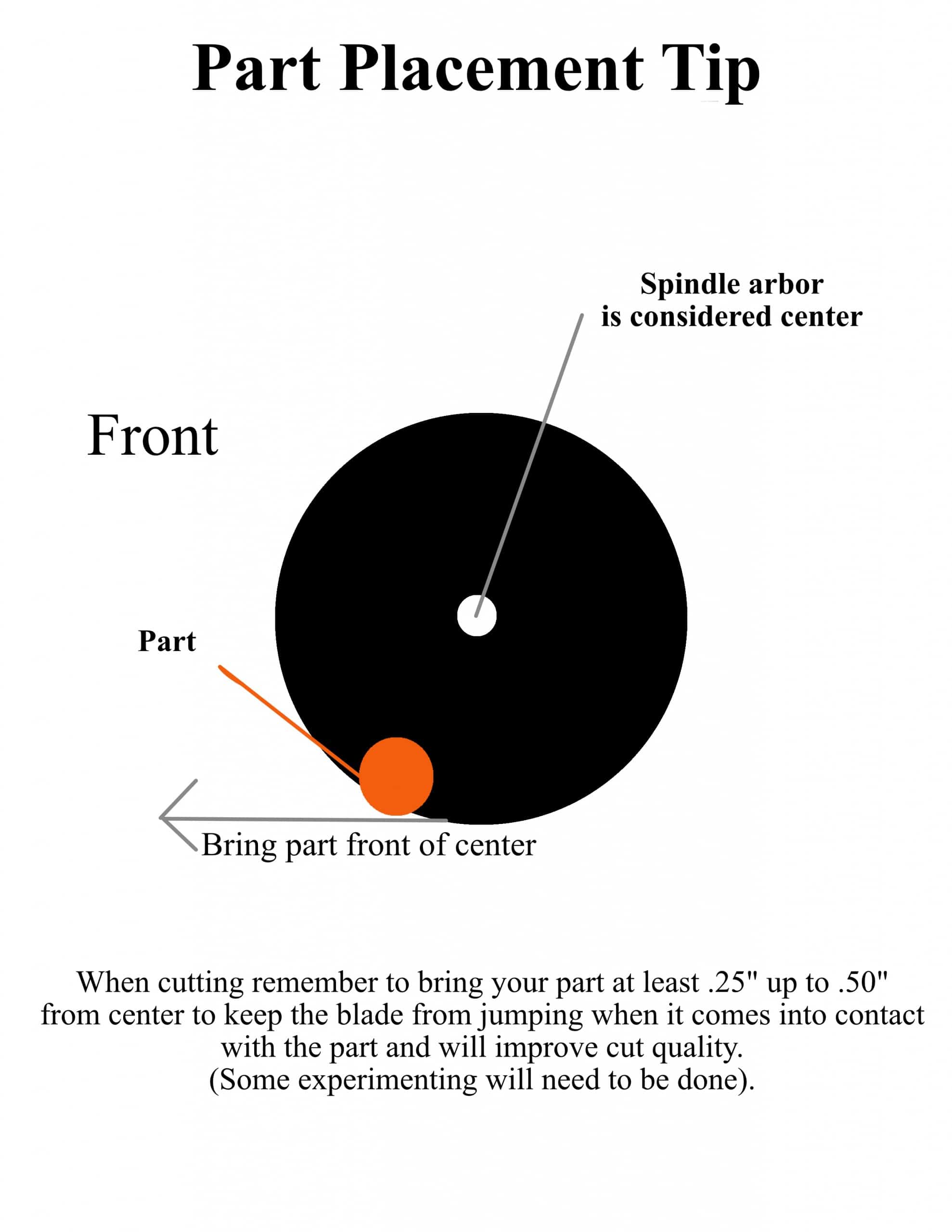

Having the part placed in your abrasive saw correctly is important. What I mean by that if your part is placed behind of center (center being the blade spindle) your part may have a tenancy to bounce and not cut properly. If you have your part placed front of center your part won’t bounce.

To help you with part placement we suggest shimming your part. This will allow you to move your part without moving the saw fence. If you move the fence and don’t square it to the blade your part might not have a straight cut. That’s why we suggest shimming your part.

Regardless if you shim your material or not you should have your material at lease 1/4″ past center.

Cleaning Your Dust Collector

Cleaning your vacuum daily is important a few different reason. In this “Useful Tips and Tricks For Your Kalamazoo Industries Industrial Equipment” post we will cover those very reason “Why you should clean your vacuum daily”.

- Cleaning your dust collector daily will help you extend the life of the motor and filter. The longer you go without cleaning more debris will collect on the filter. This will stop air getting through the filter and burn up the motor.

- A fire could be started in the cabinet. Typically when we see fires is when you mix different materials, for example: metal and wood or metal and aluminum.

- The longer you go without cleaning the dust collector the longer it will take to clean, which mean’s non-productive down time.

Stand by for more maintenance topics and other useful topics in this blog “Useful Tips and Tricks For Your Kalamazoo Industries Industrial Equipment”.