KS690HV-5 Belt Grinding Systems with Dust Collector

The Kalamazoo KS690HV is a heavy-duty 6″ × 90″ horizontal belt grinder built as a production-ready grinding system for welding and fabrication shops that need fast stock removal with controlled, repeatable results.

With a 5 HP motor and fast belt speed, it helps your team clean edges, blend welds, and prep parts for welding steel without slowing the work cell. The built-in dust collection base pulls metal debris at the source, helping keep the floor cleaner and the shop safer.

It works well in robotic welding systems and welding automation by standardizing prep before fit-up and final weld—ideal for the manufacturing industry where throughput matters.

Need a production-ready setup? Request a quote and specify voltage with Kalamazoo Industries.

The KS690HV is a heavy-duty grinding system built for the daily pace of welding and fabrication shops. With a 6″ x 90″ belt, a 5 HP motor, and high belt speed, it removes material quickly for cleaner edges and better welding steel preparation—while the built-in DCV-6 dust collector helps pull metal dust and debris down into the base, rather than allowing it to spread throughout the shop.

Equipment benefits

- Faster prep, less rework: High belt speed and 5 HP power help you knock down welds, clean plasma-cut edges, and prep parts quickly.

- Cleaner air at the source: The integrated DCV-6 dust collection system (400 CFM) captures grinding debris where it’s generated, helping to keep floors and work areas cleaner.

- Repeatable results on flat work: A long, reversible steel platen supports steady, consistent finishing across longer contact areas.

- Aggressive, controlled grinding: The serrated 8″ contact wheel (70 duro) gives a strong bite for blending, shaping, and edge work.

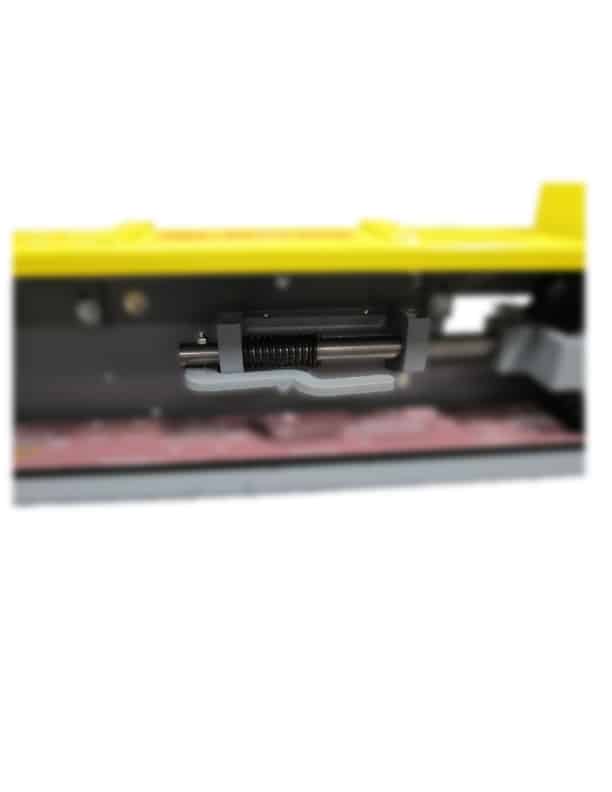

- Quick belt changes: Spring tensioning with a lever speeds up belt swaps and reduces downtime between jobs.

- Built for production cells: Fixed grinder head, all-steel build, and simple controls support reliable use in the manufacturing industry—including robotic welding systems and broader welding automation workflows where consistent part prep matters.

- Shop-ready power options: 3-phase 220/440V capability lets you match the machine to your facility power.

Motor & Power

-

5 HP, 3 PH belt sander (220/440V — specify voltage)

Belt Size

-

6″ x 90″ (compatible with all belt types)

Contact Wheel

-

8″ OD x 6″ W serrated contact wheel, 70 duro

Belt Speed

-

6900 SFPM

Bearings

-

Sealed ball bearings

Platen

-

24-1/2″ long, reversible and replaceable steel platen

Switches

-

Grinder switch: magnetic on/off switch

-

Metal dust collector switch: rotary on/off switch

Metal Dust & Debris Collector

-

Mounted on DCV-6 steel dust collector system

-

400 CFM with reusable steel mesh filter (located in base)

-

Hinged steel access door for easy debris cleanout (vacuum base)

-

Steel debris chute with 4″ vacuum port

Additional Features

-

Adjustable steel worktable

-

Removable steel belt guard

-

Work stop located on top of the machine

-

Fixed belt grinder head

-

Spring belt tensioning with lever for quick extension/retraction of grinder yoke

-

Steel side-hinged access guard

-

All-steel construction

Shipping

-

Dimensions: L 57″ x W 45″ x H 54″

-

Weight: 600 lbs.

-

Shipping weight and dimensions subject to change

Country of Origin

-

Made in the USA

The KS690HV is a heavy-duty horizontal belt grinder designed for the daily workload of welding and fabrication shops. It gives your team a fast, repeatable grinding system for weld prep and cleanup, using a wide 6″ x 90″ belt and a powerful drive to remove material quickly while keeping results consistent from part to part.

The built-in dust collection helps pull grinding dust down into the base, so the work area stays cleaner and your crew spends less time on cleanup. It also works well as a dedicated prep station ahead of robotic welding systems and other welding automation cells—supporting consistent part edges and surfaces across the manufacturing industry, especially when welding steel.

- Blend and smooth weld beads on frames, brackets, and structural weldments for a cleaner finished look

- Prep edges before fit-up by removing burrs and sharp corners on cut parts

- Remove dross and clean up plasma-cut edges so parts assemble faster and need less rework

- Clean mill scale, rust, and surface contamination from the weld zone to support better weld quality

- True and square edges to improve fixture fit and help parts sit flat before welding

- Create a consistent surface finish before paint or powder coat for better coating results

- VFD: Variable Frequency Drive

- KB69050 – 6″ x 90″, 50 grit, general-purpose aluminum oxide sanding belts (sold in packs of 10)

- KB69080 – 1″ x 42″, 80 grit, general-purpose aluminum oxide sanding belts (sold in packs of 10)

- KB142100 – 1″ x 42″, 100 grit, general-purpose aluminum oxide sanding belts (sold in packs of 10)

Additional Equipment Images and Accessories

KS690HV-5: Heavy-Duty Grinding + Dust Control

Grind aggressively. Capture metal dust at the source. Maintain consistent, shop-ready finishes.

Call (269) 382-2050 or Request a Quote today.

Made in the USA | Built for Fabrication | Proven in Metalworking Shops