BG14 Backstand Finishing Grinder

Order Now

- High material removal capability for aggressive snagging, weld blending, and casting cleanup.

- Industrial-duty construction designed for long service life in foundry and fabrication environments.

- Versatile belt configuration supports a wide range of abrasive types and grit sequences.

- Consistent finishing results improve part quality and reduce downstream rework.

- Automation-ready design allows seamless integration into industrial robot cell applications.

- Scalable production solutions that support both manual operations and automated workflows.

- Improved operator efficiency through stable tracking and controlled grinding performance.

- Made in the USA.

- Motor: 10 HP, 3-Phase

- Voltage Options: 230V or 480V (Please specify at time of order)

- Drive Type: V-belt driven system

- Switching: Magnetic on/off push button switch for operator safety

- Belt Size: 3″ x 132″

- Belt Speed: 6,300 SFPM (Surface Feet Per Minute)

- Contact Wheel: 14″ OD x 3″ Wide

- Wheel Type: 70 durometer serrated contact wheel

- Tracking: Precision single-knob sanding belt tracking

- Tensioning: Manual belt tension release lever for rapid belt changes

- Frame: Rugged, all-steel construction for industrial environments

- Setup: Designed for “Easy Setup”

- Access: Easy-to-open steel sanding belt guard for inspection and maintenance

- Cleanliness: Integrated steel parts tray and easy cleanout design

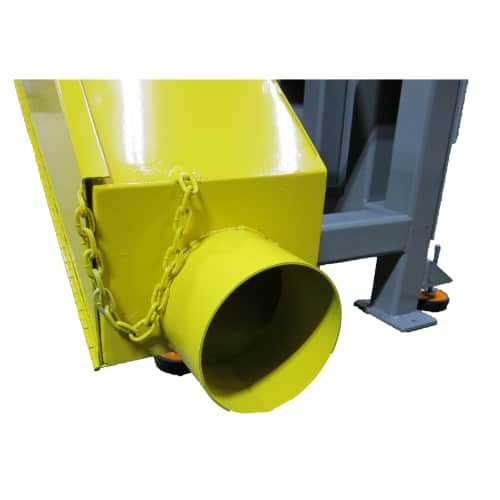

- Dust Collection: Includes a 6″ port for external dust collector hook-up

- Vibration Control: Equipped with isolation pads for smoother operation and reduced noise

- Manufacturing: Proudly Made In the USA!

- Shipping Weight: Approximately 1,000 lbs.

- Shipping Dimensions: L 39″ x W 75″ x H 65″

- Note: Shipping weight and dimensions are subject to change.

- Manufacturing: Made In the USA!

The Kalamazoo Industries BG14 Backstand Grinder is purpose-built for demanding foundry and fabrication environments where consistency, durability, and throughput matter. As a heavy-duty finishing grinder, the BG14 excels in post-casting and post-weld operations, delivering reliable material removal and surface refinement across a wide range of ferrous and non-ferrous components. Its rigid construction and straightforward backstand design make it equally effective as a standalone workstation or as part of larger production solutions focused on repeatability and operator efficiency.

Typical applications include:

-

Deburring and surface finishing of castings prior to machining or coating using a robust finishing grinder platform

-

Weld cleanup, slag removal, and edge conditioning in welding and fabrication shops with high daily throughput

-

Gating, riser, and flash removal in foundry environments requiring consistent belt tracking and grinding pressure

-

Integration into semi-automated workflows, supporting future automation solutions without replacing core equipment

-

Use as a fixed grinding station within an industrial robot cell for automated part presentation and repeatable finishing results

-

Support of lean manufacturing and scalable production solutions where uptime, simplicity, and durability are critical

The BG14 provides a practical, industrial-grade grinding solution that bridges manual craftsmanship and automation-ready manufacturing, making it a dependable asset for foundries and welding and fabrication operations seeking long-term performance and flexibility.

- Variable frequency drive

- Cast iron work table part number (829 -057)