The Kalamazoo Industries KM16-18 18″ abrasive saw is a rugged, high-performance cutting tool. It’s built specifically for the needs of metal fabricators who demand strength and precision. This saw is also a trusted choice for professionals who are metal fabricators and welding shops. It’s designed to handle tough jobs with consistency and control.

One of its standout features is its ability to perform clean, accurate angle iron cutting. The KM16-18 is a manual mitre saw, giving users the flexibility to make mitre cuts. This makes it especially useful for projects used in custom metal fabrication, where detail and accuracy are critical.

With its powerful 10HP 3PH motor and 18″ abrasive blade, the KM16-18 cuts through heavy materials with ease. Its solid clamping system keeps workpieces secure during operation. Built for industrial environments, it’s tough enough for daily use. Whether you’re cutting tubing, pipe, or structural steel, this saw delivers dependable results every time.

Motor

- 10 HP, 3 Phase

- 230 and/or 460 Volts

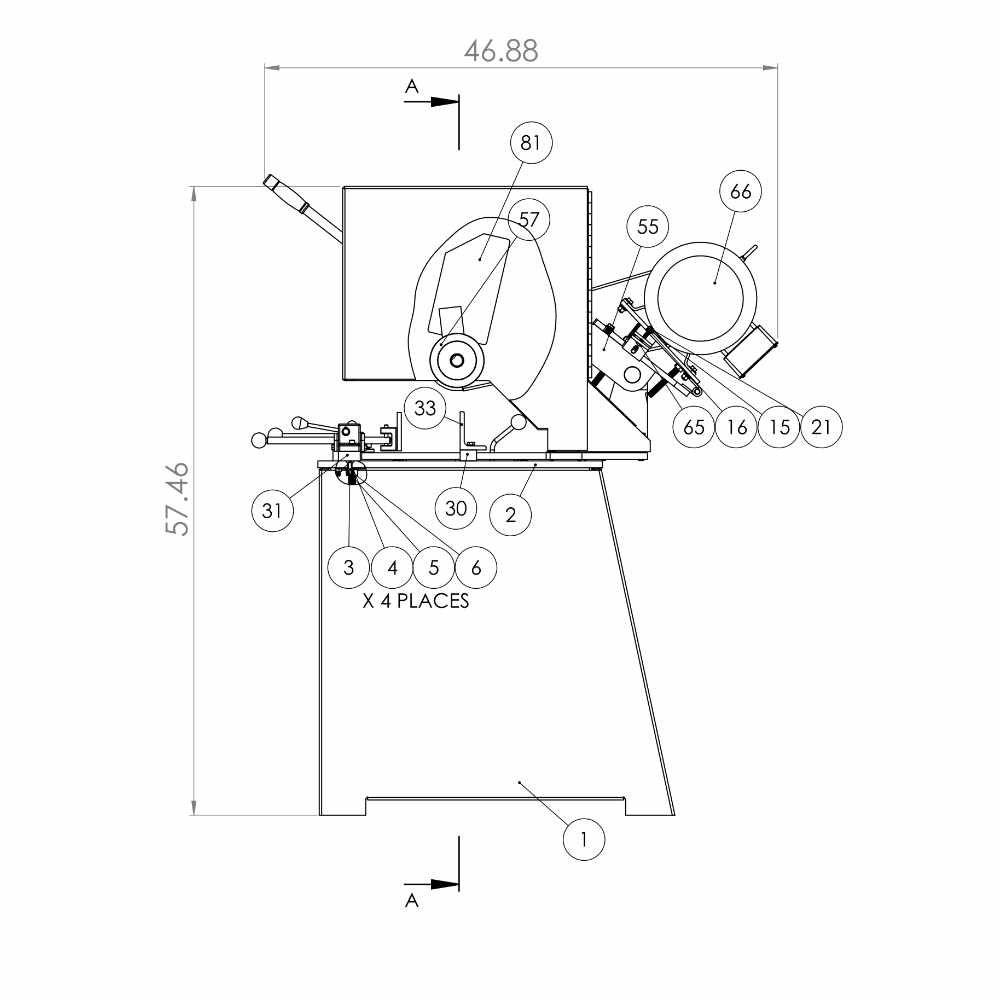

Mitre Capabilities

- Mitres left and right: 0° to 45°

- Positive index holes with locking pin

- Lever lock for table positioning

Spindle & Wheel

- Spindle Speed: 2500 RPM

- Spindle Arbor: 1″

- Wheel Capacity: 16″ to 18″ abrasive blades

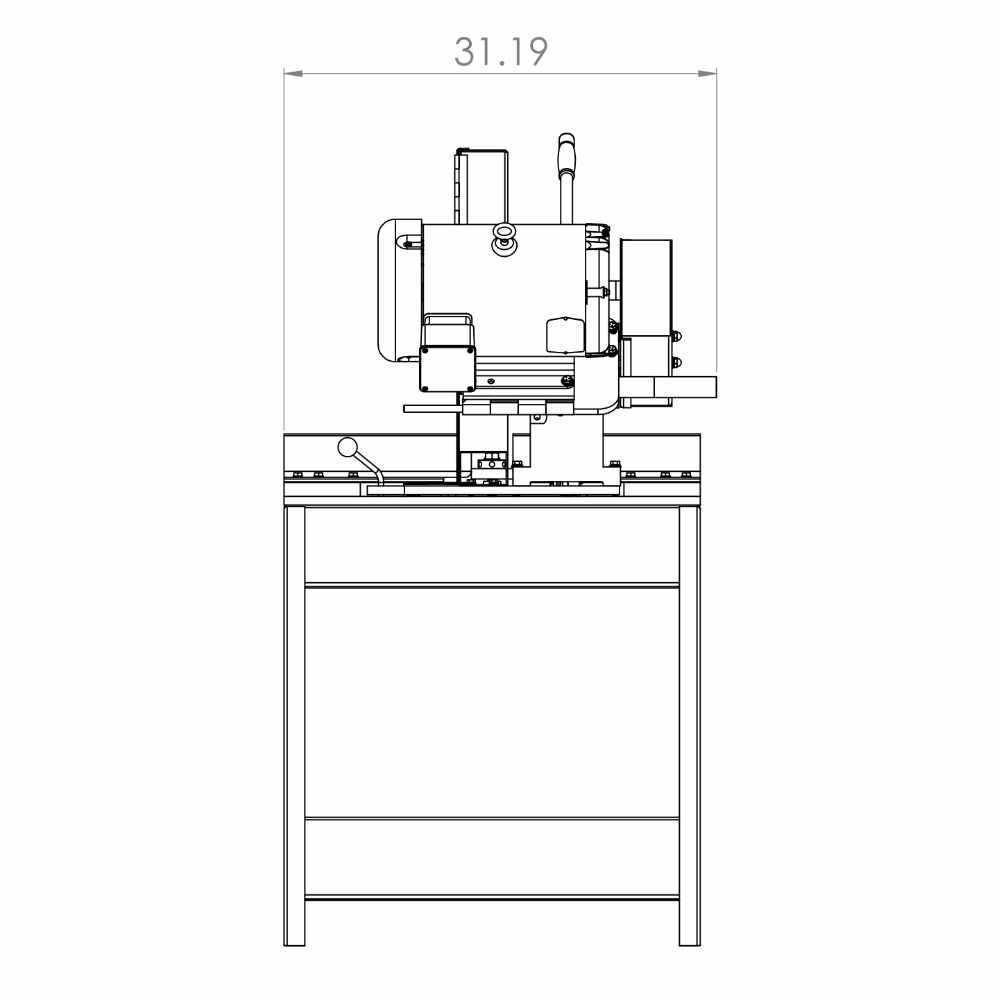

Construction

- Heavy-duty steel base

- Rugged cast iron arm

- Rugged cast iron trunnion

- Dual heavy-duty cam lock vises

- Adjustable up and down stops

Cutting Capacities (mild steel)

- At 90°:

- 3″ solid steel

- 4-1/2″ pipe

- At 45°:

- 2-1/2″ solid steel

- 3-3/4″ pipe

Controls

- Magnetic push-button on/off switch

Shipping Information

- LTL Skid Dimensions: L 53″ x W 41″ x H 74″

- LTL Skid Weight: 850 lbs.

- Shipping weights and dimensions are subject to change.

Country of Origian

- Made in Kalamazoo, MI, USA

The Kalamazoo KM16-18 18-Inch Steel Cutting Mitre Saw is a powerhouse tool built for demanding industrial environments. Engineered for strength and precision, this manual mitre saw is a trusted solution for high-volume cutting in fabrication shops, steel service centers, manufacturing facilities, metal fabricators and welding shops. Known as a top-rated industrial chop saw, the KM16-18 delivers consistent performance and long-term durability.

Designed with metal fabricators in mind, it excels in a wide range of applications—from structural steel and pipe to angle iron cutting and heavy-wall tubing. Its rugged frame and replaceable components make it a reliable choice for operations that require both power and longevity. Whether you’re working in metal fabrications and welding or handling repetitive production tasks, this saw is built to keep up.

The KM16-18 is especially well-suited for custom metal fabrication, where precision mitre and straight cuts are essential. Its cutting capabilities make it a versatile asset in any industrial setting.

Key Cutting Capabilities and Tasks:

- Cuts solid mild steel up to approximately 2-1/2″ at a 45° mitre angle

- Handles steel tubing up to approximately 3-3/4″ at 45°, with even greater capacity at 90°

- Ideal for cutting structural steel, angle iron, pipe, and heavy-wall tubing

- Designed for both mitre and straight cuts in ferrous materials

- Perfect for repetitive, high-volume industrial cutting tasks

The Kalamazoo KM16-18 is more than just a saw—it’s a reliable workhorse built for professionals in metal fabricators, metal fabrications and welding, and custom metal fabrication environments. Designed for precision and durability, this manual mitre saw is ideal for high-volume cutting tasks where accuracy and efficiency are essential. Whether you’re performing angle iron cutting or working with structural steel, the KM16-18 delivers consistent results in even the toughest industrial settings.

Why Fabricators Choose the KM16-18:

- Built for Metal Fabricators: Engineered to meet the daily demands of fabrication shops, steel service centers, and manufacturing facilities.

- Precision Mitre Cutting: Offers accurate mitre and straight cuts, making it ideal for custom metal fabrication projects.

- Heavy-Duty Performance: Handles solid steel, pipe, and angle iron cutting with ease—even under high-volume workloads.

- Manual Mitre Saw Control: Gives operators full control for clean, consistent cuts in ferrous materials.

- Durable Construction: Rugged frame and replaceable components ensure long-term reliability in harsh environments.

- Versatile Applications: Perfect for professionals in metal fabrications and welding shops who need a dependable, all-purpose cutting solution.

Daily Maintenance

- Inspect abrasive blade for wear, cracks, or damage.

- Check blade alignment and ensure it is securely mounted.

- Clean the saw table and surrounding area of metal shavings and debris.

- Ensure mitre lock handle and trunnion pin move freely and lock securely.

- Check for unusual vibrations or noises during operation.

Weekly Maintenance

- Inspect V-belts for wear and proper tension (should have ~½” of squeeze).

- Lubricate moving parts such as the trunnion.

- Check electrical connections for signs of wear or overheating.

- Verify blade guard is functioning properly and not obstructed.

Monthly Maintenance

- Inspect bearings (e.g., K10 and K12 bearings) for smooth operation.

- Check motor ventilation for dust buildup and clean if necessary.

- Inspect and clean eccentric and concentric bushings on the mitre table.

Quarterly Maintenance

- Check alignment of the saw head and mitre angles.

- Inspect the motor junction box for secure wiring and no corrosion.

- Review and tighten all bolts and fasteners on the frame and table.

- Replace worn abrasive blades with the correct grit and bond for your material.

Safety Reminders

- Do NOT use steel/carbide-tipped blades – abrasive blades only.

- Ensure workpiece is slightly ahead of wheel center to avoid climb cutting.