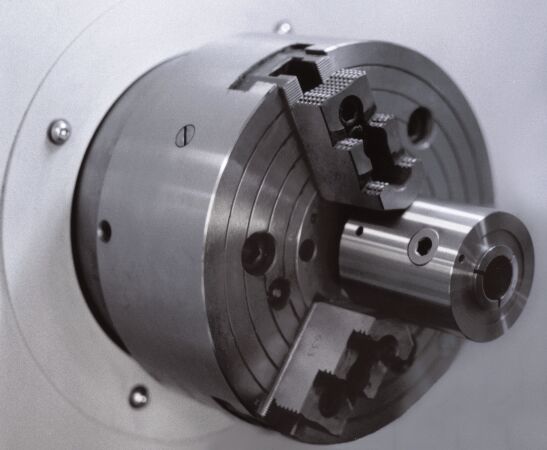

The Kalamazoo Industries 1CC 5C Collet Chuck Fixture is a rugged, precision-engineered solution built for performance and reliability. Designed to securely hold 5C collets, this 5C collet fixture is ideal for short-run machining and demanding applications. Whether you’re outfitting a tool room, machine shop, or production line, this 5C manual collet fixture delivers the speed, accuracy, and repeatability you need.

Versatile in design, it can be used in a manual chuck or integrated into an air-operated chuck system, making it a flexible choice for a wide range of setups. As a dependable lathe collet chuck, it stands out as one of the best options for machinists who demand precision, durability, and consistent performance.

Quick-Action Locking Mechanism

Engage and release your 5C collet with a simple half-turn of the front-mounted locking ring—no tools required. This intuitive design saves time and reduces operator fatigue.

Heavy-Duty All-Steel Construction

Built to withstand the demands of industrial use, the 1CC features hardened and ground surfaces for long-lasting precision and durability.

Flexible Mounting Options

The rear of the 1CC fixture features precision-drilled and tapped holes for fast, secure mounting to a custom base plate or the AT1CC fixture mounting plate. This design allows for seamless integration into a wide range of machining setups.

Compatible with:

- 4th axis rotary tables

- Vertical mills

- Horizontal mills

- CNC machining centers

- Manual and CNC lathes

Shipping

- Shipping Weight: 7 lbs.

- Shipping Dimensions: 6″ L x 5″ W x 6″ H

- Shipping weight and dimensions are subject to change.

Country of Origin

- Made in USA!

Fast Setup & Changeover

Engineered for short-run production, the Kalamazoo Industries 1CC 5C Collet Fixture is built for speed and efficiency. There’s no need to remove your existing chuck—simply mount this 5C manual collet fixture directly into your power or manual chuck for quick changeovers that keep your workflow moving.

Dead-Length Design for Precision

This collet holding fixture features a dead-length design that eliminates axial movement during clamping, ensuring consistent part positioning. It’s ideal for precision machining where repeatability is critical—making it a trusted choice for tight-tolerance applications.

Flexible Mounting Options

Designed for versatility, this lathe collet chuck can be mounted on vertical or horizontal mills, machining centers, 4th-axis rotary tables, and more. It includes tapped holes and a pilot recess for secure fixture mounting, giving you the flexibility to adapt it to your setup.

High Accuracy Performance

Hardened and ground for minimal runout, this CNC lathe collet chuck delivers the accuracy serious machinists demand. Performance may vary depending on collet and workpiece conditions, but it remains a top-tier solution for shops that prioritize precision.

Built to Last

Crafted from all-steel, hardened and ground components, this 5C collet fixture is built for long-term durability. It holds 5C collets securely and reliably, cycle after cycle.

Made in the USA

Proudly American-made, this fixture reflects quality craftsmanship and long-term support. With replaceable cams and screws available regardless of unit age, it’s a 5C manual collet fixture you can count on for years to come.

This maintenance checklist is designed to ensure the optimal performance and longevity of the Kalamazoo Industries 1CC 5C Collet Chuck. Follow the daily, weekly, and monthly tasks outlined below, along with safety checks, lubrication, and inspection points.

Weekly Maintenance

- Inspect the collet for signs of wear or damage and replace collet if necessary.

- Check the spindle for smooth operation.

- Inspect the chuck jaws for wear and replace if necessary.

Monthly Maintenance

- Perform a thorough inspection of the collet chuck and all its components.

- Check the condition of the collet and replace it if it is worn or damaged.

- Inspect the spindle and chuck jaws for wear and re-bore if necessary.

- Disassemble fixture and apply rust preventative oil moving parts to prevent rust and check for smooth operation.

Inspection Points

- Collet condition

- Spindle operation.

Chuck jaws wear & accuracy.