welding equipment

-

A fabricator that can find the right abrasive belt for the next job. Their many different belts available and each job and each style will give you a different finish. Their are :

A fabricator that can find the right abrasive belt for the next job. Their many different belts available and each job and each style will give you a different finish. Their are :- Open Coat Belt- this form of sanding belt has gaps and spaces so the material won’t clog the belt. This abrasive belt is used mostly with woodworking.

- Closed Coat Belt– this form of sanding belt doesn’t have gaps or spaces which make this sanding belt is designed and manufactured for sanding or grinding metals.

-

Providing exact advice on how to get optimal performance from an abrasive cutoff saw is very difficult because each application is unique. Rough guidelines, however, can help a metal fabricator understand the cutting process, troubleshoot problem areas, and determine the right equipment for the cutting job. Download the free eBook now to read more.

Providing exact advice on how to get optimal performance from an abrasive cutoff saw is very difficult because each application is unique. Rough guidelines, however, can help a metal fabricator understand the cutting process, troubleshoot problem areas, and determine the right equipment for the cutting job. Download the free eBook now to read more. -

Ebook: Cutoff Saw Creates Blanks from Superalloy's in Seconds

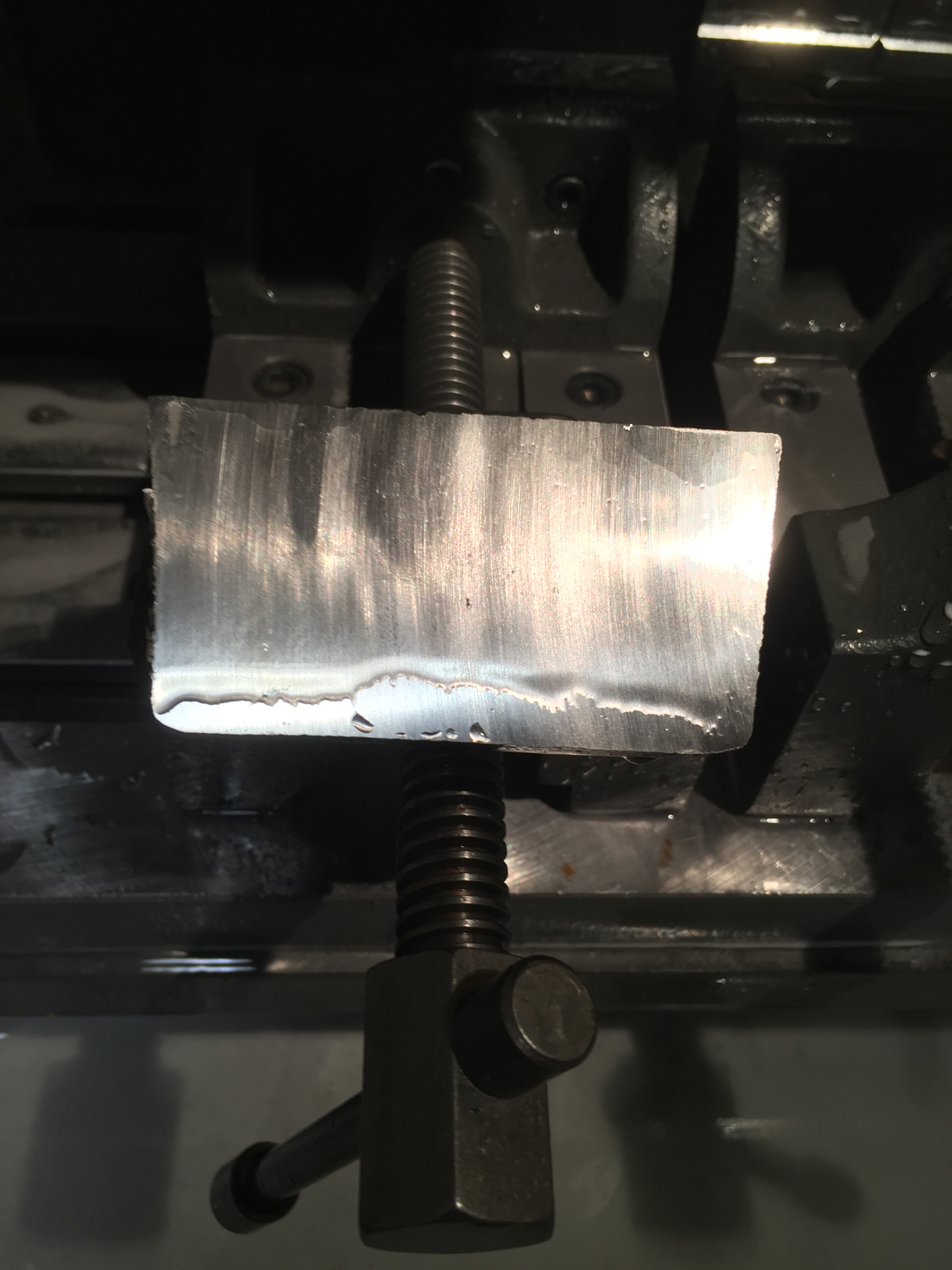

The superalloy inconel is valued for its strength and heat resistance, but these properties also make it difficult to machine. Northern A-1 Services, a recycling company with facilities throughout Northern and Western Michigan and in Pennsylvania, needed to saw inconel bar stock without using coolant to create casting charges on a just-in-time (JIT) delivery schedule for an aerospace customer. Given the time constraints—and sawing operation in general—the company realized it would need a better cutoff saw than what it had. As a result, the company turned to Kalamazoo Industries of Kalamazoo, Michigan, to develop a cutoff saw capable of dry-cutting inconel bar stock in a matter of seconds rather than minutes. As it turns out, the 12-feet-tall cutoff saw Kalamazoo Industries delivered with a 75-hp motor and 36-inch-diameter abrasive wheel turned a challenging operation into a repeating source of job-shop-type revenue for the recycling company. Down load for free to read the whole article. -

AR-36 index ring

$53.00AR-36 index ring -

AR-24 indexing ring

$53.00AR-24 indexing ring -

AR-20 Indexing ring

$53.00AR-20 Indexing ring for 5C, A1, RT, RTBA and RTBB index fixtures.