Boost your shop’s efficiency and precision with the K10HS 10 inch non ferrous saw—a powerhouse designed for speed, accuracy, and durability. Whether you’re cutting aluminum extrusions, copper piping, or brass stock, this high-performance aluminum cutting saw delivers clean, burr-free cuts every time. As a versatile aluminum cutting chop saw, it’s ideal for fabrication shops, machine shops, and production lines looking to streamline operations. Need a saw to cut copper pipe or handle brass cutting with ease? The K10HS is built to handle it all with high-speed precision and minimal maintenance. Don’t let outdated tools slow you down—upgrade your workflow today with the K10HS and experience the productivity boost your shop deserves. Explore the K10HS now and see the difference precision engineering makes.

- Precision Engineered for Non-Ferrous Metals: Delivers clean, accurate cuts on aluminum, copper, brass, and other soft metals.

- Powerful 10-Inch Blade: Ideal size for versatility without sacrificing cutting depth or control.

- Powerful Motor: Maintains consistent speed and power for smooth, burr-free finishes when paired with the correct high-speed, carbide-tipped blade for your material.

- Built-In Material Clamping System: Reduces vibration and enhances safety during operation.

- Durable Construction: Built for industrial use with long-lasting components and minimal maintenance needs.

- Compact Footprint: Space-saving design perfect for workshops, job sites, and fabrication shops.

- Versatile Cutting Applications: Suitable for extrusions, tubing, pipe, and flat stock.

- Clean Work Area: Integrated chip collection helps maintain a tidy and safe workspace.

- Made in the USA

Motor Options

- 3 HP, 3-Phase (220V or 440V)

- 3 HP, 1-Phase (110V or 220V)\

- Note: Please specify phase and voltage when ordering.

Performance

- Spindle Speed: 3450 RPM

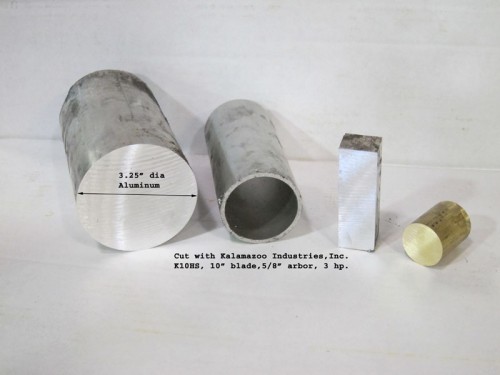

- Saw Material Capacity: 3.25″ solid/pipe

- Blade Type: High-speed carbide blade (not included)

- Spindle Arbor: 5/8″

- Drive System: V-belt driven with spindle and motor pulleys

- Bearings: Sealed ball bearings

Construction

- Arm: Cast aluminum

- Trunnion: Cast iron

- Base: Heavy-duty cast iron

- Blade Depth Adjustment: Threaded up/down stops

- Vise: Cam lock vise

- Guarding: Retractable clamshell guard

- Switch: Manual on/off switch

- V-Belt Guard: Included

The K10HS 10 inch non ferrous saw is built for professionals who demand precision, speed, and versatility across a wide range of metalworking tasks. Whether you’re in a fabrication shop, plumbing business, or custom manufacturing environment, this saw delivers clean, accurate results with minimal cleanup. As a dedicated aluminum cutting saw, it excels at slicing through extrusions, tubing, and sheet stock with ease. Its compact design and powerful motor also make it a go-to aluminum cutting chop saw for job sites where space and time are limited. For tradespeople needing a reliable saw to cut copper pipe, the K10HS offers smooth, burr-free cuts that reduce prep time and improve joint quality. It’s equally effective for brass cutting, making it a versatile solution for anyone working with non-ferrous metals.

Common Applications:

- Aluminum cutting for extrusions, profiles, and sheet stock

- Copper pipe cutting for plumbing, HVAC, and mechanical installations

- Brass cutting for decorative metalwork, fittings, and components

- Precision cuts in soft metals for fabrication and manufacturing

- On-site and in-shop use as a compact, high-performance 10 inch non ferrous saw

- Ideal as an aluminum cutting chop saw for fast, clean cuts in production environments

- Trusted saw to cut copper pipe with minimal burring and excellent edge quality

- 12-O steel stand for K10B/K10HS saws

Q: What materials can the K10HS cut?

A: The K10HS is designed specifically for non-ferrous metals. It excels at cutting aluminum, copper, brass, and other soft metals. It is not intended for cutting ferrous materials like steel or iron.

Q: What size blade does the K10HS use?

A: It uses a 10-inch carbide-tipped blade, specifically optimized for non-ferrous metal cutting. Always select the appropriate blade for your material to ensure clean, burr-free cuts.

Q: Can this saw be used as an aluminum cutting chop saw?

A: Yes, the K10HS functions exceptionally well as an aluminum cutting chop saw, delivering fast, accurate cuts on extrusions, and tubing.

Q: Is this a good saw to cut copper pipe?

A: Absolutely. The K10HS is a reliable saw to cut copper pipe, offering smooth cuts that reduce the need for deburring and improve joint quality.

Q: How does it perform for brass cutting?

A: The saw is highly effective for brass cutting, providing clean, precise results on fittings, rods, and decorative components.

Q: Is the saw portable or stationary?

A: The K10HS has a compact footprint, making it suitable for both stationary use in workshops and portable use on job sites.

Q: Does it come with a clamping system?

A: Yes, it features a replaceable single cam lock vise.

Q: What kind of maintenance does it require?

A: The K10HS is built with durable components and requires minimal maintenance. Regular blade checks and cleaning of the chip collection system are recommended.

Q: What industries or trades is this saw best suited for?

A: It’s ideal for metal fabrication, plumbing, HVAC, electrical work, and any trade that involves frequent cutting of non-ferrous metals.

Shipping Information

Shipping Information

- Shipping Weight: 150 lbs.

- Shipping Dimensions: 30” L x 36” W x 25” H

- Weight and dimensions are subject to change

Machine Footprint

Machine Dimensions

- Machine Depth: 20″

- Machine Width: 10″

- Machine Height: 24″