K20E Enclosed Wet Inspection Saw

If your shop needs clean, repeatable cut samples without making a mess, the K20E is built for the job. This enclosed, heavy-duty cutoff machine uses coolant to keep parts cool and control grit, so it’s a reliable wet inspection saw for daily quality checks and lab-style sample prep.

It’s a smart fit for heat treat facilities that need consistent sections for hardness checks and microstructure review, and it’s also ideal when you need to inspect bearings, or you’re inspecting ball bearings after failure, because the controlled, wet cut helps protect the evidence on the part instead of overheating it. From tough steel to precision components like linear rails, the K20E helps cut with confidence, keep your work area cleaner, and get results you can trust.

Want cleaner samples and more dependable inspections? Contact Kalamazoo Industries today to get pricing, options, and help choosing the right setup for your shop.

Order Now

If you run a busy shop, the K20E helps you cut tough parts cleanly and safely while keeping heat down and giving you a clear view of the cut. It’s a reliable wet Inspection saw built for accurate sample prep and everyday production work.

It’s a great fit for heat treat facilities, bearings, and inspecting ball bearings after failure. With wet cutting and an enclosed design, you get smoother cuts, less dust, and less heat that can change your material. It also handles long stock like linear rails with stable support for straighter results.

Key benefits for shop owners:

- Cleaner, cooler cutting to reduce heat and protect your sample

- Enclosed design helps control splash and abrasive mess for a safer work area

- More consistent results for inspection work and metallurgical samples

- Great fit for heat treat facilities where repeatable cuts matter

- Strong option for bearings and inspecting ball bearings after failure

- Cuts linear rails to customer specs with stable support and solid build quality

- Built for day-in, day-out shop use—less hassle and more confidence at the cut

- Made in USA

Ready to tighten up your inspection process and speed up prep work? Contact Kalamazoo Industries for a quote and make the K20E your go-to wet Inspection saw.

Motor Options:

- 15HP or 20HP 3-phase motor

- Available in 230V or 460V (specify voltage at the time of order)

Controls:

- Magnetic controls

- 24V on/off push buttons

Accessibility:

- Side access ports on infeed and outfeed sides of equipment for long stock

- Front and side access doors

Drive System:

- V-belt drive

Spindle Arbor:

- 1″ saw spindle arbor (1.25″ arbor also available)

Bearings:

- Ball bearings sealed spindle bearings

Material Capacities:

- 4″ solid

- 6″ shapes

- Based on mild steels

Vise:

- Air chain vise

Coolant System:

- Flood coolant system

- Industrial 1/4HP pump

- Machine wash down hose

- 24-gallon steel tank

- Two flexible coolant hoses

Additional Features:

- Oscillation

- Internal light

- Manual stock feed

Feed System:

- Air/oil power down feed system (0-12 FPM feed rate) with temporary override button for quicker blade descent

- Adjustable down stop to limit the depth of cut

Equipment Dimensions & Weight:

- Machine shipping dimensions: D 50″ x W 54″ x H 89″

- Machine Shipping Weight: K20E-15HP machine weight: 1900 lbs.

- Machine weight and dimensions are subject to change.

Origin:

- Made in the USA

If you need clean, repeatable cuts for inspection work, the K20E is built for the job. As a wet inspection saw, it uses a fully enclosed cabinet and flood coolant to keep grit and coolant contained while helping reduce heat and burrs—so your samples stay closer to “as-cut” condition for checking hardness, grain, and defects.

It’s a strong fit for heat treat facilities and busy shops that need controlled, consistent cutting on tough parts every day.

Common K20E applications:

- Cut heat-treat coupons and test pieces for QA checks in heat treat facilities.

- Section bearings for troubleshooting and root-cause work, including inspecting ball bearings after failure.

- Chop and section long stock using the side access ports—great for cutting linear rails and other long, straight parts.

- Cut solid bar and structural shapes when you need a controlled feed and steady clamping (air chain vise + air/oil downfeed)

- Keep mess down in the shop or lab with an enclosed design, internal light, and flood coolant system.

Want to see if the K20E fits your parts and workflow? Request a quote through Kalamazoo Industries (or call 800-592-2050) and tell us what you’re cutting and your material size.

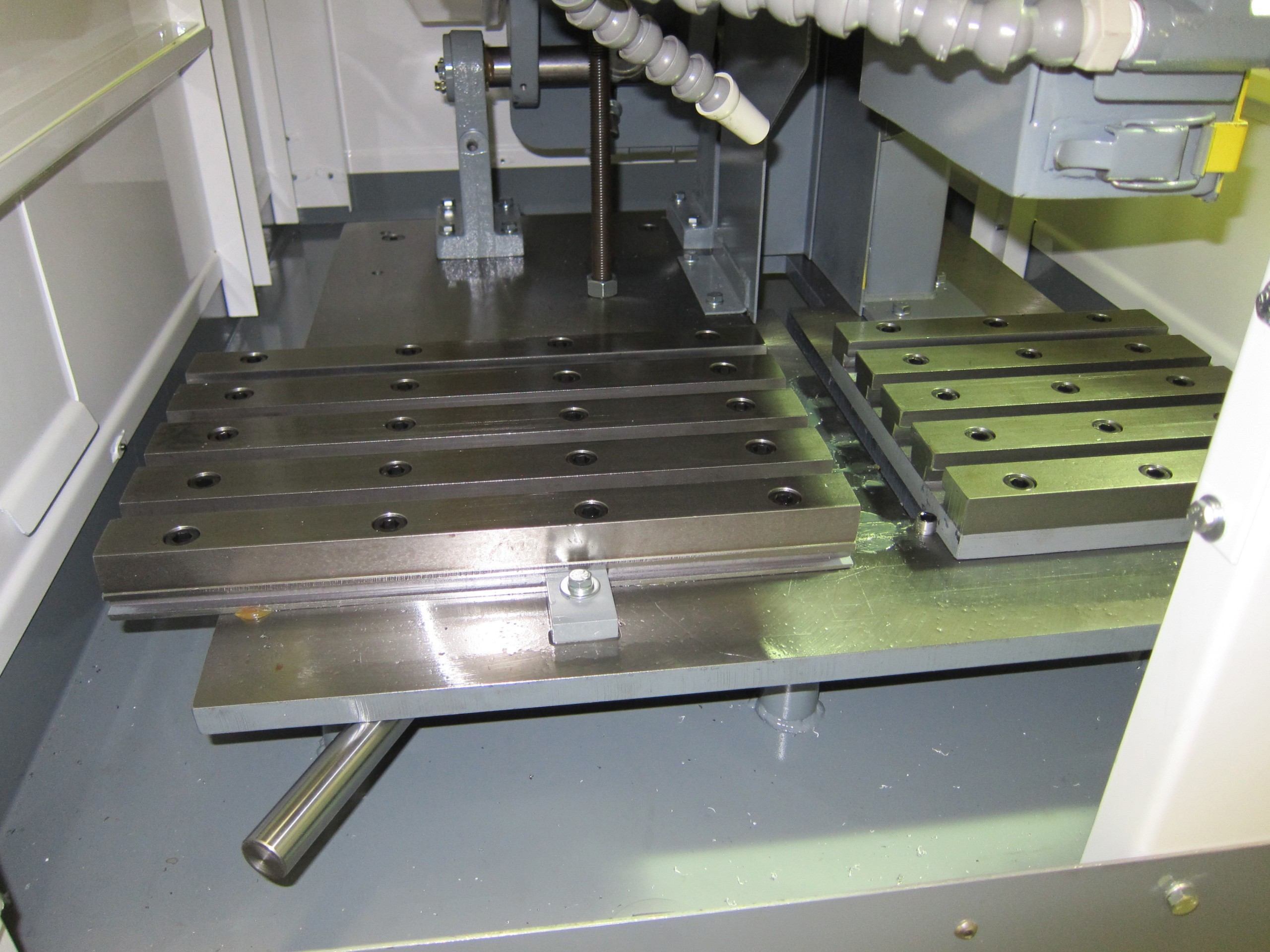

- 829-054 sliding X-Axis t-slot table. Right side of table is fixed.

- KW2 spindle wrench

- 710-052 door safety interlocks: Prevent the doors from opening while the saw is operating.

- TS-20 t-slot table

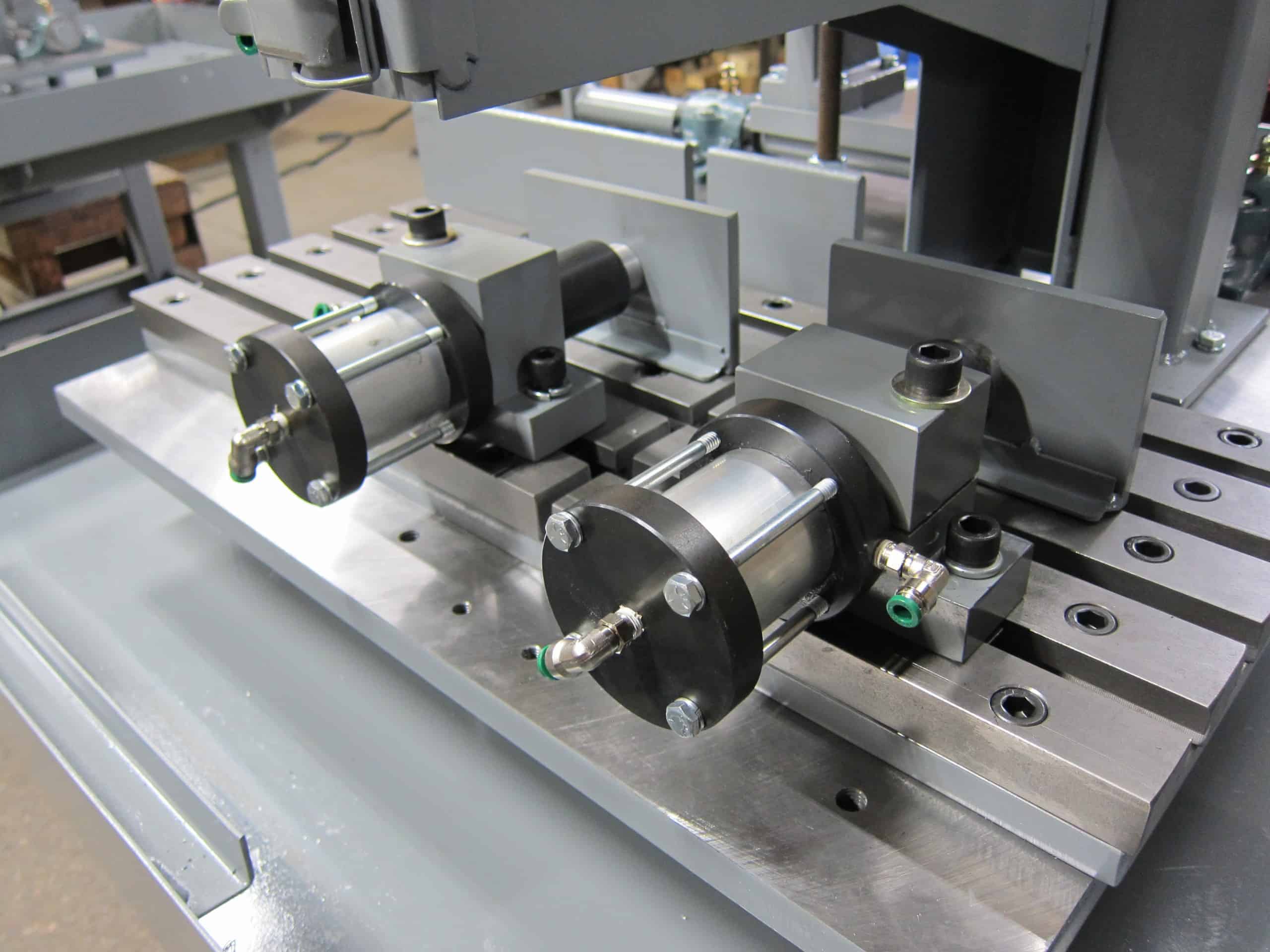

- AV-20 air operated jawed vise

Additional Equipment Images and Accessories

Built for Wet Cutting in Metallurgical Inspection & Failure Analysis

Cut samples cleanly for fast, reliable inspection without overheating the material.

Call (269) 382-2050 or Request a Quote today.

Made in the USA | Built for Inspection & Sample Prep | Proven in Metalworking Labs