S612 Industrial Combination Machine

Discover why the Kalamazoo S612 combination machine is the smart machining solution every machine shop needs. This top machine is built to handle tough jobs, save time, and deliver consistent results across all your sanding tasks. Perfect for any industrial machine shop, the S612 helps you get more done with less effort.

Key Benefits:

-

All-in-one performance: Belt and disc sander in one combination machine saves space and increases efficiency.

-

Versatile sanding power: Smoothly sands various materials—metal, wood, and composites—with professional results.

-

Built for durability: Heavy-duty steel and cast-iron construction stand up to daily shop use.

-

Faster workflow: Quick belt changes and easy adjustments keep production moving.

-

Precision results: Achieve smooth, accurate finishes every time.

- Made in USA

Take your machine shop to the next level—upgrade to the S612 today and experience the productivity boost your team deserves!

Power & Controls

-

Main Motor Options

-

3 HP, 1-phase, 230 V — 12 A

-

3 HP, 3-phase, 230/460 V — 8 A / 4 A

-

-

Switch: Magnetic push-button ON/OFF

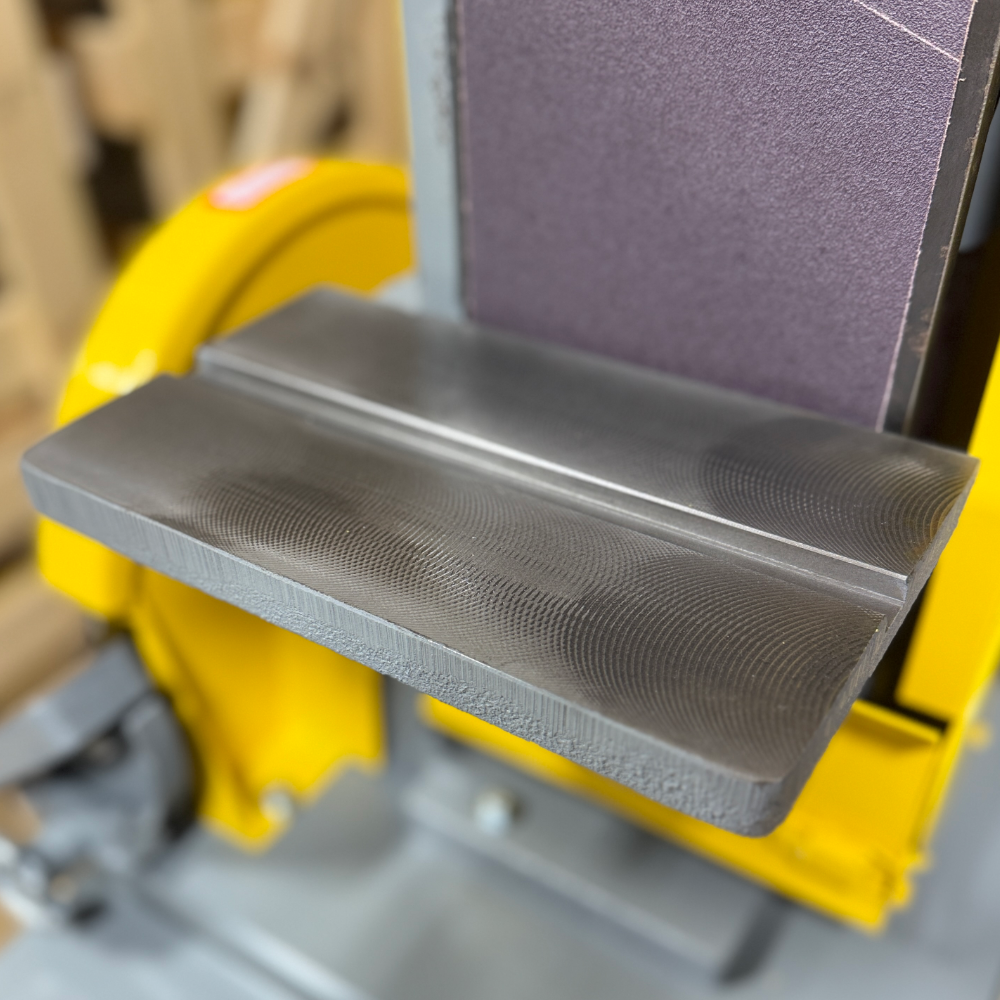

Belt Sander

-

Belt size: 6″ × 48″

-

Speed: 2,800 SFPM

-

Changeover: Quick-change belt with pre-tensioned one-lever release

-

Positions: Horizontal & vertical (multi-position)

-

Platen: 6.5″ × 14″ steel, reversible & replaceable

-

Work table: 6″ × 10″ cast iron with 5/8″ miter slot

Disc Sander

-

Disc diameter: 12″ with 5/8″ arbor

-

Speed: 2,500 SFPM

-

Work table: 7.75″ × 16.5″ cast iron with 5/8″ miter slot

Construction & Dust Collection

-

Heavy-duty steel base with access door for vacuum cleanout

-

Integrated dust collector: 100 CFM with replaceable filter

-

Drive: Dual V-belt system

Dimensions & Shipping

-

Overall dimensions: 12″ L × 14″ W × 60″ H*

-

Shipping weight: 425 lb

-

Shipping size: 45″ L × 33″ W × 65″ H

-

Shipping weight and dimensions are subject to change.

Country of Origin

-

Made in USA

- MG-6 mitre gauge

- KD1250– 12″, 50 grit, general-purpose aluminum oxide sanding disc (sold in packs of 10)

- KD1280 – 12″, 80 grit, general-purpose aluminum oxide sanding disc (sold in packs of 10)

- KD12100 – 12″, 100 grit, general-purpose aluminum oxide sanding disc (sold in packs of 10)

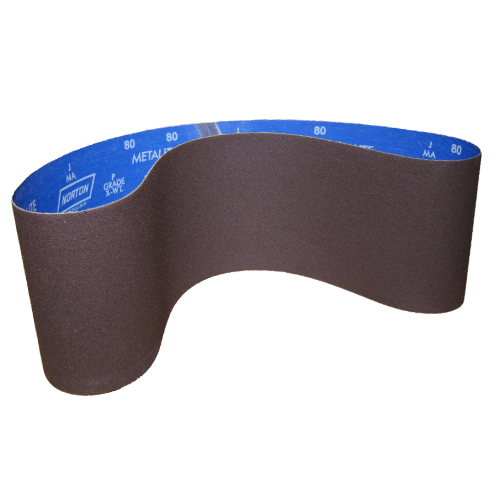

- KB64850 6″ x 48″ 50 grit, general-purpose aluminum oxide sanding belt (sold in packs of 10)

- KB64880 6″ x 48″ 80 grit, general-purpose aluminum oxide sanding belt (sold in packs of 10)

- KB648100 6″ x 48″ 100 grit, general-purpose aluminum oxide sanding belt (sold in packs of 10)

The Kalamazoo S612 combination machine is the perfect machining solution for shop owners who need versatility and speed in one top machine. Designed to handle a wide range of sanding and finishing tasks, it’s built to help your machine shop stay efficient and deliver quality results every time. Ideal for any industrial machine shop, the S612 makes it easy to take on more jobs with confidence and precision.

Common Applications:

-

Metal fabrication: Smooth welds, deburr edges, and prep surfaces for coating or assembly.

-

Woodworking: Shape, sand, and finish parts for custom or production projects.

-

Maintenance and repair: Clean, refinish, and restore parts quickly and accurately.

-

Tool and die work: Fine-tune precision components and maintain consistent finishes.

-

Prototyping and production: Quickly move from rough shaping to final finishing with one setup.

Streamline your operations and save valuable shop time—add the S612 to your lineup today and see how one powerful machine can do it all!