Abrasive Saw-Cutting Tips for Efficiency and Safety

Achieving clean and efficient cuts with your abrasive saw requires the right techniques and tools. Here are some essential tips to ensure bright, non-discolored cuts and maintain the longevity of your abrasive cutoff wheel:

1. Blade Selection Matters:

- Use the correct abrasive cutoff wheel for your specific metal to avoid discoloration and burning.

- If you experience discoloration, consult your abrasive cutoff wheel representative for guidance.

2. Proper Spindle Nut Handling:

- Do not hammer the spindle nut tight; hand tighten only.

- Avoid using impact wrenches, as over-tightening can lead to issues and affect the performance of the abrasive cutoff wheel.

3. Utilize Paper Blotters:

- Place paper blotters on both sides of the abrasive cutoff wheel for added protection and improved performance.

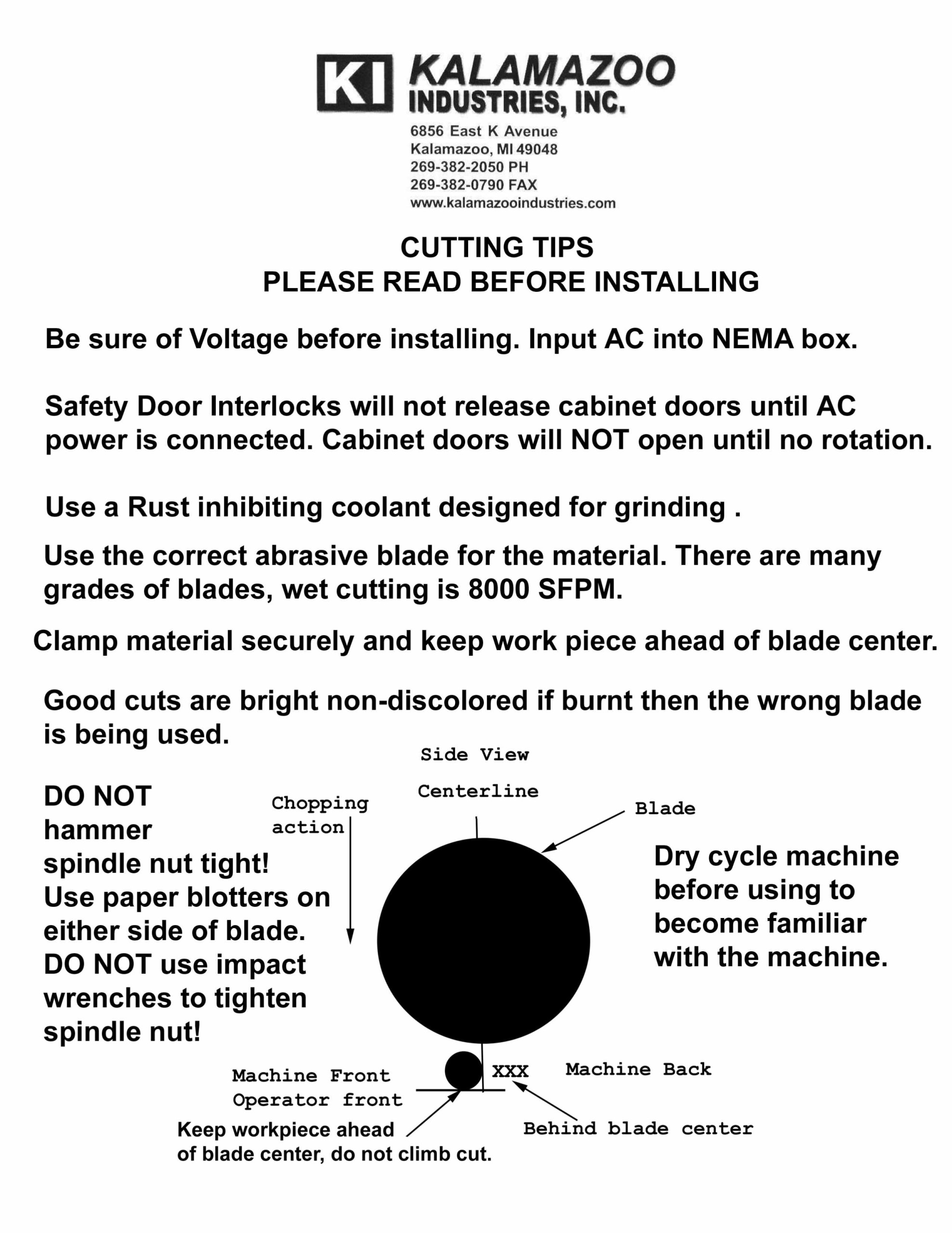

4. Workpiece Placement:

- Keep the workpiece ahead of the saw blade center (spindle arbor) to enhance the cut and ensure a secure grip between the saw fence and table.

- Avoid placing the workpiece behind the blade center to prevent climb cutting, which can compromise the material and the cut quality.

5. Seek Expert Advice:

- If you’re unsure about the abrasive cutoff wheel suitable for your metal, reach out to your saw manufacturer for recommendations and direct you to a trusted abrasive cutoff wheel supplier.

Remember, following these tips not only ensures cleaner cuts but also contributes to the overall safety and efficiency of your abrasive saw cutting. Happy cutting!