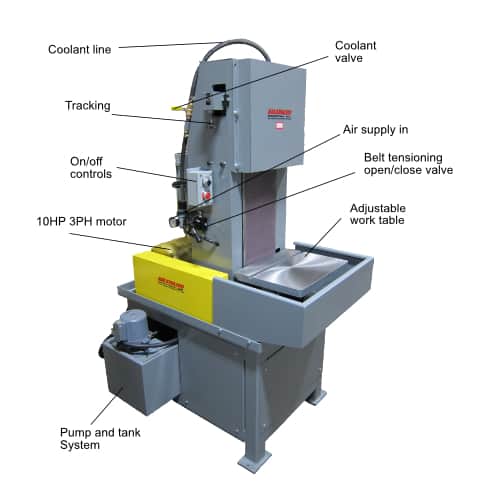

S14W Vertical Wet Machine

The Kalamazoo S14W is built for shops that need power, speed, and control in one tough machine. As one of our top wet machines, it uses coolant to keep parts cool, reduce dust, and extend belt life. With wide wet sanding belts, this surfacing machine makes quick work of weld cleanup, deburring, and polishing—turning big jobs into real time savers. Whether you’re working aluminum, exotic alloys, or finishing stainless steel for a clean, professional look, the S14W helps you deliver better results with less rework. Ready to boost your shop’s output? Contact Kalamazoo Industries today for a quote and put the S14W to work for you.

Parts Store

The Kalamazoo S14W is built for shops that need strength, speed, and precision every day. As one of our most advanced wet machines, it combines high horsepower with coolant-assisted sanding to give you a cleaner, safer, and faster workflow. With wet sanding belts, you get smoother finishes, longer belt life, and cooler parts—perfect for finishing stainless steel and other metals. This heavy-duty surfacing machine is designed to be one of your shop’s biggest time savers, cutting down on rework and getting parts out the door faster.

Key Benefits

-

Keeps parts cooler while reducing dust and sparks

The S14W uses coolant to wash over the belt and part. This means less heat build-up, less chance of warping, and far fewer sparks in your shop. It also keeps the air cleaner by trapping metal dust before it spreads. -

Extends the life of your wet sanding belts

Because the belts run cool and stay clean, they cut longer without clogging. That means fewer belt changes, less downtime, and lower abrasive costs over the life of the machine. -

Delivers consistent results when finishing stainless steel and exotic alloys

Whether you’re building food equipment, medical parts, or aerospace components, the S14W gives you an even, repeatable finish. It’s especially effective for finishing stainless steel, where heat and scratch patterns can ruin a part. -

Large 14″ × 103″ belt covers more area in fewer passes

The wide belt design works as a true surfacing machine, letting you grind, blend, and polish bigger parts quickly. More coverage per pass means you spend less time on each job. -

Built to last—rugged design, high power, nonstop performance

With a 20 HP motor and heavy-duty frame, the S14W is engineered for production floors. It’s one of our toughest wet machines, ready to run all day, every day. -

A true time savers tool for busy production shops

By reducing rework, extending belt life, and getting parts finished faster, the S14W pays for itself in time saved. Operators spend more time producing and less time fixing mistakes or waiting on belt changes.

Motor Specifications

- Power: 20 HP, 3 PH TEFC

- Voltage: 220V or 440V (specify voltage at time of order)

Sanding Belt Specifications

- Size: 14″ x 103″ (wet)

- Speed: 3400 SFPM

Platen Work Surface

- Dimensions: 14″ x 32″

Belt Tension

- Type: Air-powered

- Pressure Required: 0-55 PSI

Controls

- Type: Magnetic with jog feature

Construction

- Material: Heavy-duty steel

- Drive: V-belt driven

- Splash Guard: Steel

Coolant System

- Tank Size: 45 gallon (steel)

- Pump Specification: 1/4HP

- Coolant Splash Bar: Flow control ball valve

- Coolant: Includes anti-rusting agent to keep materials cool and prevent steel from rusting

Additional Features

- Part Replacement: Quick and easy

Shipping Information

- Weight: 1900 lbs.

- Dimensions: 75″ L x 55″ W x 66″ H

- Shipping weight and dimensions are subject to change

Country of Origin

- Made in USA

- KWB1410350– 14″ x 103″, 50 grit, general-purpose wet aluminum oxide sanding belts (sold in packs of 10)

- KWB1410380 – 14″ x 103″, 80 grit, general-purpose wet aluminum oxide sanding belts (sold in packs of 10)

- KB14103100 – 14″ x 103″, 100 grit, general-purpose wet aluminum oxide sanding belts (sold in packs of 10)

The Kalamazoo S14W is built for shop owners and operators who need a tough, reliable machine that works hard all day. As one of our wet machines, it delivers cooler grinding, cleaner finishes, and longer belt life. Using wet sanding belts, you can power through heavy jobs faster, making it one of your best time savers. Whether you’re finishing stainless steel to a food-grade shine or running flat parts on a large surfacing machine, the S14W is ready for the job.

Applications include:

-

Weld cleanup and blending on large fabricated parts

-

Finishing stainless steel for medical, food, and energy industries

-

Deburring and flattening plates, brackets, and components

-

Heavy stock removal with extended belt life using wet sanding belts

-

Large-part workholding on a wide surfacing machine table

-

High-production shops needing reliable time savers for daily use

Upgrade your shop’s capabilities today with the Kalamazoo S14W. Request a quote now and see how this wet machine can save time, improve finishes, and give your team the edge.